13 Oct Distran helps ENGIE streamline outage management at Al Ezzel power plant in Bahrain

Distran helps ENGIE streamline outage management at Al Ezzel Power Plant in Bahrain

Reduced downtime, optimized safety for staff, and more efficiency by using the Distran Ultrasonic Camera as a preventive maintenance tool.

ENGIE is a global leading energy company with key businesses in gas, renewables, and services. With more than 96,000 employees, the enterprise generated a turnover of 93.9 billion euros in 2022. Among other major projects in the Middle East, ENGIE operates Al Ezzel, a 950 MW Combined Cycle Gas Turbine (CCGT) power plant in Bahrain.

Distran helps ENGIE streamline power plant outage management at Al Ezzel in Bahrain

Reduced downtime, optimized safety for staff, and more efficiency by using the Distran Ultrasonic Camera as a preventive maintenance tool.

ENGIE is a global leading energy company with key businesses in gas, renewables, and services. With more than 96,000 employees, the enterprise generated a turnover of 93.9 billion euros in 2022. Among other major projects in the Middle East, ENGIE operates Al Ezzel, a 950 MW Combined Cycle Gas Turbine (CCGT) power plant in Bahrain.

How to make outage management more efficient?

As availability and reliability are essential for every power plant, planned outages need the best possible preparation. Therefore, Engie relied on the Distran Ultrasonic Camera to conduct a detailed survey at the Al Ezzel plant to master various challenges:

RELIABILITY

To find as many gas leaks as possible, even in difficult-to-access areas.

SPEED

To complete the survey in a much shorter time than with previous approaches.

EFFICIENCY & SAFETY

To enable the maintenance team to work efficiently and safely.

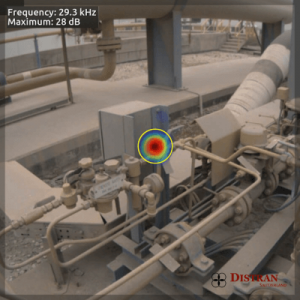

Different from traditional gas leak detection technologies such as soap spray, sniffers, or infrared cameras, Distran Ultrasonic Cameras harness the Acoustic Leak Imaging (ALI), technology. Hence, they use ultrasounds to detect leaks of all gas types from safe distances.

Learn more about the different models (Ultra Pro, Ultra Pro X, and Ultra CE) in the Products section.

Leak detection for all parts of the plant

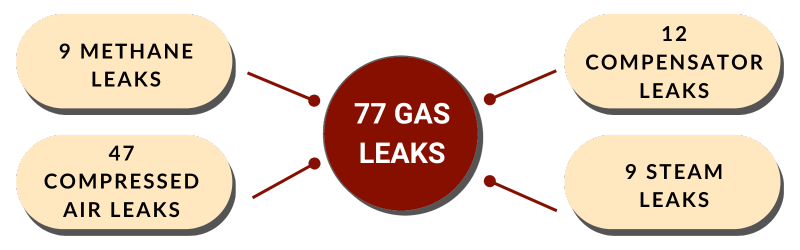

Acoustic gas leak detection makes contact with the gas obsolete, which simplifies the detection of gas leaks. At Al Ezzel, the team in charge of the survey inspected four gas units and two steam units. Within the five days of the survey, they found:

- 9 methane leaks

- 47 compressed air leaks

- 12 compensator leaks

- 9 steam leaks

Thanks to the Distran Ultrasonic Camera, the team managed to spot previously unnoticed leaks of various types, sizes, and locations. They completed the inspection of a very large area with a variety of difficult-to-access equipment such as turbines, silo burners, heat recovery steam generators, and compressed air systems.

Increase your inspection speed, reliability, and safety with Distran Ultrasonic Camera.

Increase your inspection speed, reliability, and safety with Distran Ultrasonic Camera.

“Thanks to Distran’s innovative, easy-to-use, and effective technology, we have already been able to increase the efficiency and safety of our facilities.”

James Barrett

General Manager at Al Ezzel Power Plant

ENGIE

“Thanks to Distran’s innovative, easy-to-use, and effective technology, we have already been able to increase the efficiency and safety of our facilities.”

James Barrett

General Manager at Al Ezzel Power Plant

ENGIE

Predictive maintenance made easier

Compared to traditional methods that often require scaffolding, the team accomplished the mission very quickly. The efficient and accurate acoustic site monitoring with the Distran Ultrasonic Camera turned out to be a significant help:

- The maintenance team was able to address all the discovered issues during the next planned outage.

- They could prioritize the maintenance activities based on size, location, and other data related to the detected.

Distran Ultra Pro ultrasonic camera pinpoints the leaks from a safe distance,

without the need for scaffolding.

A thorough leak search is not only crucial for a plant’s efficiency and availability but also for maintaining a safe working environment.

Learn more about why inspection specialists in Oil & Gas, Chemical Industry, Composite Engineering, Aerospace, industries relying on hydrogen processing, and other fields detect gas leaks with Distran.