Speed up vacuum leak inspection

Composite manufacturing requires a perfect vacuum, as any leak in a bag can compromise the final product quality and will require additional time for repair. The traditional leak detection methods are tedious, time-consuming and heavily user-dependent.

Including a software dedicated to specific needs of composite manufacturers, the hand-held Ultra CE detects leaks at a distance and with unmatched speed. Ultra CE excels in finding leaks in noisy areas.

Ultra CE’s 124 microphones detect ultrasounds and reconstruct the location of the sound source, i.e. the leak. Combining the acoustic information with the wide-angle optical camera, the precise location of the leak is shown on the screen on the back of the ultrasound camera.

The real-time visualization enables staff to fix leaks efficiently. The recorded images and videos can easily be used for reporting purposes.

Detects leaks in seconds at a distance, even in folds:

Detection distance

30 cm to 50 m

or 1 to 165 ft

Angle of view

180°

Accuracy

1°

Battery life

5 hours

Ultrasonic Vacuum Leak Detection

Pinpoint vacuum leaks without scanning each single square centimeter

Acoustic Leak Imaging is a technique that allows you to analyse the sound emitted by leaks, determine their exact location, and display them on the camera’s screen.

Ultrasonic Vacuum Leak Detection

Pinpoint vacuum leaks without scanning each single square centimeter

Acoustic Leak Imaging is a technique that allows you to analyse the sound emitted by leaks and display it as an image.

Benefits

Why use Ultra CE?

10 times faster than traditional methods

Traditional methods to detect vacuum leaks, such as human hearing or ultrasonic detectors with headphones, require the operator to thoroughly check every potential leak point with the risk of missing leaks. With ultrasound imaging, detection is performed at a distance, much faster and leak locations are clearly visible on screen.

Uncover leaks in bag folds

As sound propagates, hidden leaks in folds that are hardly found with other techniques can be detected with ultrasound imaging.

Repeatable and efficient method

Ultra CE is an easy-to-use device, so anyone can find leaks reliably, even at a distance. Survey images are self-explanatory.

Robust to surrounding noise

Ultra CE actively filters background noises and detects leaks even in noisy areas such as production halls.

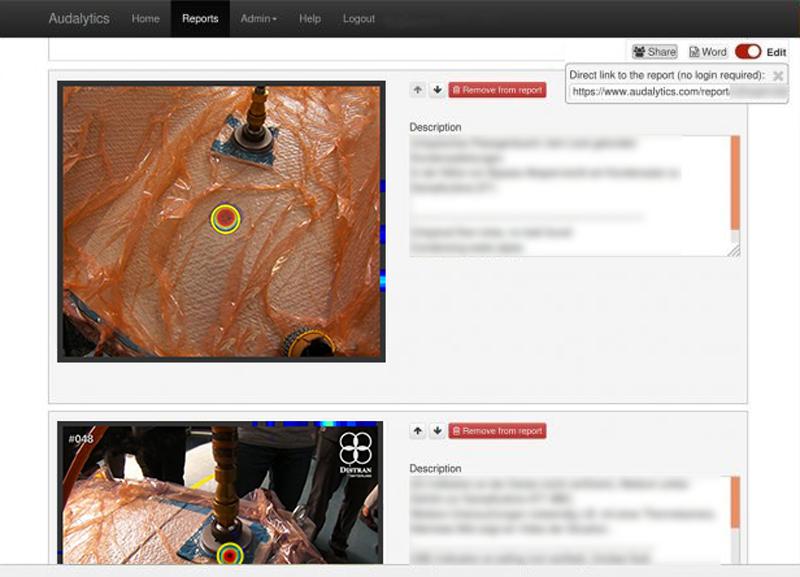

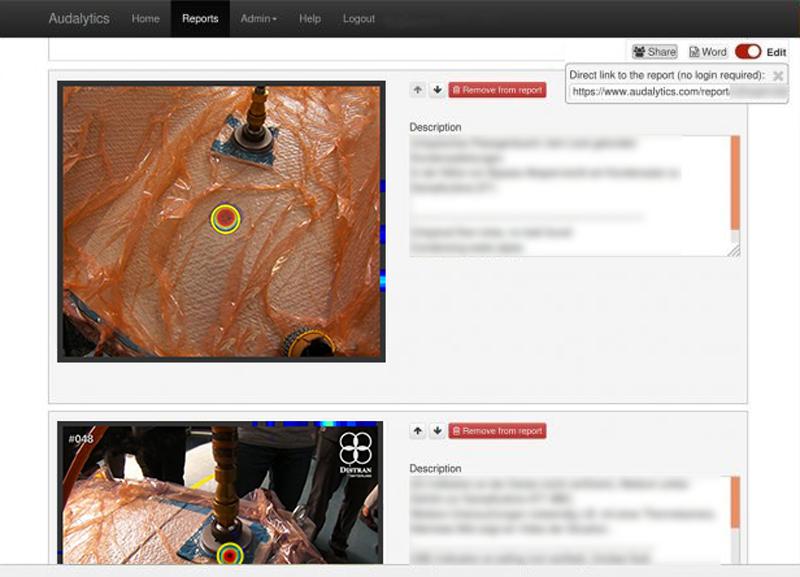

Inspection reports with Audalytics

Ensure traceability through digital reporting

Images say more than a thousand words when it comes to finding leaks. To keep track of these findings, Distran offers an integrated reporting tool ; Audalytics. It enables the operator to create a report embedding pictures, videos, and notes within minutes after the inspection.

Operators can then share their findings with their team, directly in the browser where videos are embedded seamlessly (without requiring an additional software). Special software features allow data-trending, dashboard functions and recording of voice notes.

Inspection reports with Audalytics

Ensure traceability through digital reporting

Images say more than a thousand words when it comes to finding leaks. To keep track of these findings, Distran offers an integrated reporting tool ; Audalytics. It enables the operator to create a report embedding pictures, videos, and notes within minutes after the inspection.

Operators can then share their findings with their team, directly in the browser where videos are embedded seamlessly (without requiring an additional software). Special software features allow data-trending, dashboard functions and recording of voice notes.

Production hall Distran camera compartment

Enable a permanent availability of your camera with Ultra Ready: wall mounted box with dual charger

Ultra Ready is a protective wall-mounted box, compatible with Ultra CE. It holds 2 built-in battery chargers.

Placed in a production hall, Ultra Ready makes the Distran’s camera accessible to any operator when a leak is suspected or when every part has to be checked.

Two batteries can be charged in parallel at full charging speed, away from dust.

ULTRA CE DATA

Technical specifications

–

Working distance | From: 0.3 - 50 m (1 - 165 ft) |

Lower limit of detection | Quiet environment 2 L/h (0.1 ft³/h) |

Angle of view | 180° |

Angular detection accuracy | < 1° |

Battery life | 5 hours (2.5h x 2 batteries) |

Charging duration | 70% after 1 hour, 99% after 3 hours |

Weight | 1.5 kg (3.3 lb) |

Temperature range | -10°C to 50°C (10°F to 122°F) |

Integrated LED lights | 1400 lumens |

Pictures & videos export | Audalytics or SD card |

File formats | Pictures (JPEG) and videos (MP4) |

Input methods | Button and touchscreen |

Wireless modules | Wifi 802.11 b/g/n |

Accessories | Compatible with Distran Ultra Ready |

Certification | CE, RoHS and WEEE compliant |