Detecting hydrogen leakages from a safe distance

Hydrogen is enjoying an unprecedented momentum as many countries directly support investment in hydrogen technologies. Hydrogen production, storage and transportation pose technical challenges, as hydrogen is highly flammable and checking for leaks is an essential step for its safe use.

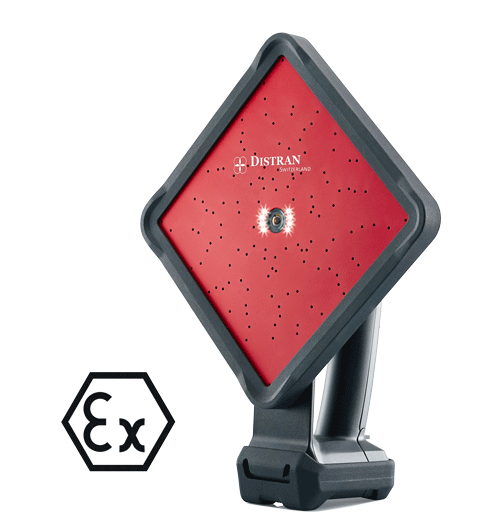

Ultra Pro X enables operators to perform fast and safe inspections as it provides operators with the exact location of each leak, from a distance. The Distran technology is also efficient outdoors and is ATEX certified (intrinsically safe).

The challenges with hydrogen

A highly flammable gas, prone to escape

- Hydrogen has a low ignition energy.

- It possesses a very broad flammability range, from 4% to 74% concentration in air,

making it much more explosive than methane for instance. - This is a tiny molecule, stored at high pressures (between 200 and 1000 bar / 2900 to 14500 psi). Coupled with the metal embrittelment phenomenon, the risk of leaks is therefore greatly increased.

- Hydrogen has no odor nor color, making a leak indiscernible.

Methods based on gas detection are not adapted

Hydrogen gas detectors requires the gas to enter the detector. Portable sniffers put operators at risks by being within potential dangerous zones. Outdoors, fixed detectors have high chance of missing hydrogen leaks, as the gas is lighter than air and quickly escape. Infrared detectors (including OGI cameras) do not detect hydrogen, as H2 does not absorbs infrared, like any homonuclear diatomic molecules (N2, O2, etc.).

With these methods, the risk of not detecting a leak is high and the time spent in inspections is long.

The challenges with hydrogen

A highly flammable gas, prone to escape

- Hydrogen has a low ignition energy.

- It possesses a very broad flammability range, from 4% to 74% concentration in air,

making it much more explosive than methane for instance. - This is a tiny molecule, stored at high pressures (between 200 and 1000 bar / 2900 to 14500 psi). Coupled with the metal embrittelment phenomenon, the risk of leaks is therefore greatly increased.

- Hydrogen has no odor nor color, making a leak indiscernible.

Methods based on gas detection are not adapted

Hydrogen gas detectors requires the gas to enter the detector. Portable sniffers put operators at risks by being within potential dangerous zones. Outdoors, fixed detectors have high chance of missing hydrogen leaks, as the gas is lighter than air and quickly escape. Infrared detectors (including OGI cameras) do not detect hydrogen, as H2 does not absorbs infrared, like any symmetrical diatomic molecules (N2, O2, …).

With these methods, the risk of not detecting a leak is high and the time spent in inspections is long.

Detect Hydrogen leaks from a distance

Detecting hydrogen leaks meters away

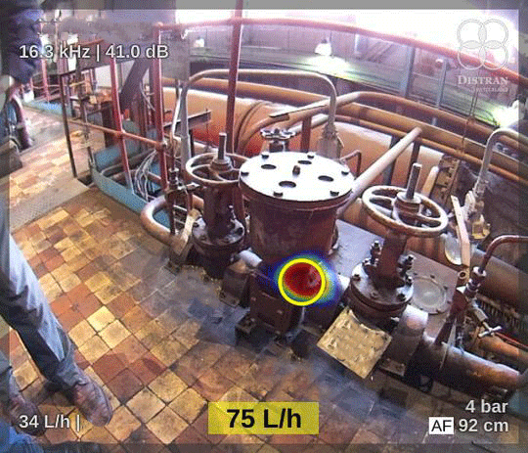

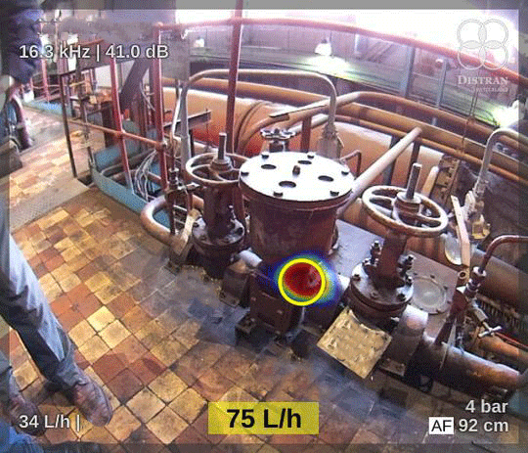

Left: a hydrogen leak on a flange, detected by Ultra pro X within a refinery

The location of the leak is clearly indicated on the picture (circled in yellow).

Detect Hydrogen leaks from a distance

Detecting hydrogen leaks meters away

A hydrogen leak on a flange, detected by Ultra pro X within a refinery

The location of the leak is clearly indicated on the picture (circled in yellow).

Why our clients use Ultra Pro X

Arkema: “Ultra Pro X enables us to significantly improve our performances”

“We gained in terms of reactivity during interventions and in terms of production. For instance, the search for hydrogen leaks used to take 4 to 5 days, but with the Distran camera, 2 to 3 hours are enough.

The acoustic camera allows us to detect leaks very easily, it has become an indispensable tool to improve our production performance on a daily basis.”

Bernard Favard

Technical Exploitation Manager ATE – ARKEMA Mont, France

Why our clients use Ultra Pro X

Arkema: “Ultra Pro X enables us to significantly improve our performances”

“We gained in terms of reactivity during interventions and in terms of production. For instance, the search for hydrogen leaks used to take 4 to 5 days, but with the Distran camera, 2 to 3 hours are enough.

The acoustic camera allows us to detect leaks very easily, it has become an indispensable tool to improve our production performance on a daily basis.”

Bernard Favard

Technical Exploitation Manager ATE – ARKEMA Mont, France

Key advantages for hydrogen leak detection

ALSO EFFICIENT OUTDOORS

CLEAR LEAK PINPOINTING

ATEX / INTRINSICALLY SAFE

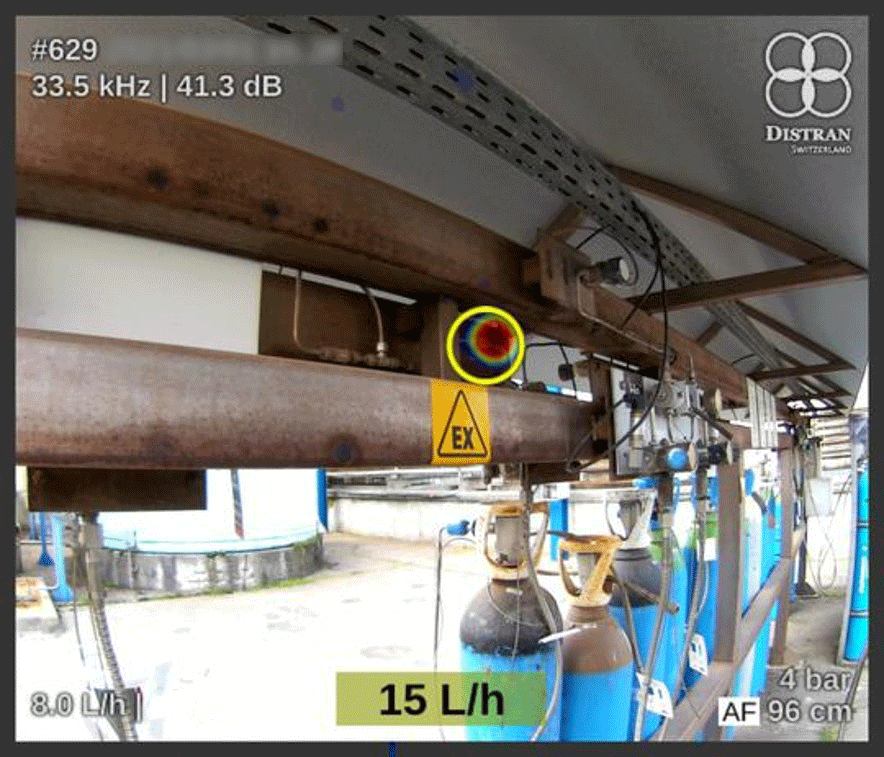

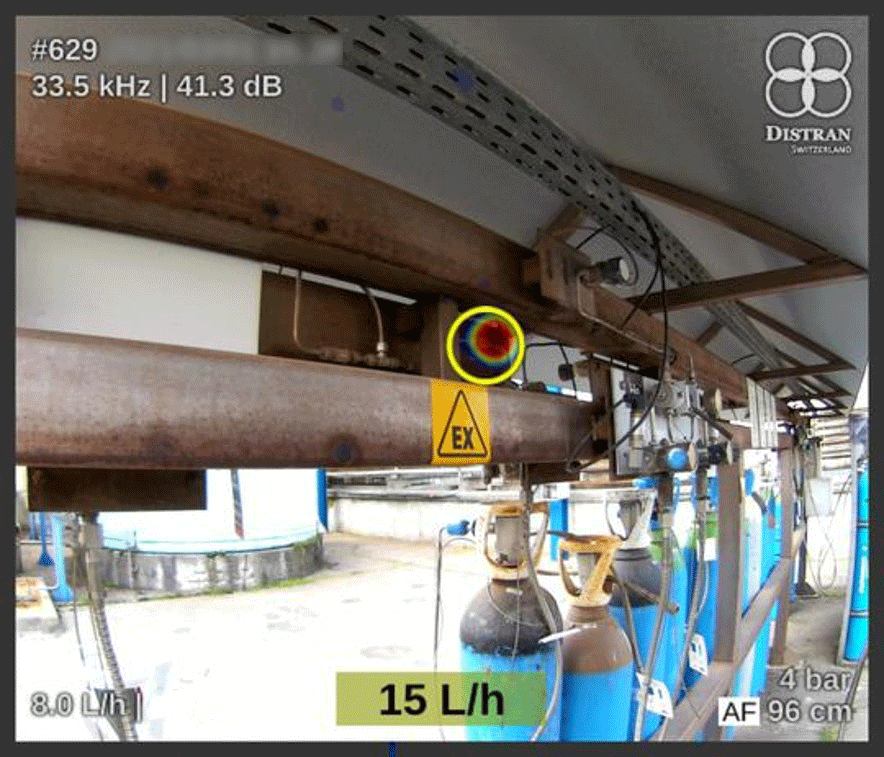

Hydrogen leaks found within refineries

Hydrogen leak found on hydrogen storage bottles

Key advantages for hydrogen leak detection

ALSO EFFICIENT OUTDOORS

Hydrogen leak found within a refinery

CLEAR LEAK PINPOINTING

Hydrogen leak found within a refinery

ATEX / INTRINSICALLY SAFE

Hydrogen leak found on hydrogen storage bottles

Key data

Detect leaks from a distance

- From 30 centimeters to 100 meters (1 to 300 feet)

- Typical distance of work, from 4 to 6 meters (13 to 20 feet)

Ultra Pro X pinpoints hydrogen leaks from the sound they make. The operator is able to spot leaks from a safe distance, without requiring to make contact with the gas.

Find small leaks

- 1 L/h at 1 meter (6.10-4 cfm at 3 feet)

- 5 L/h at 5 meters (3.10-3 cfm at 16 feet)

Ultra Pro requires a pressure differential of ~50 mBar to detect leaks.

Anyone can perform inspections

- Ultra Pro X is not user dependent

- There is no room for misinterpretation of leak indications provided

- Reduction of the impact of emissions on the environment and your plant’s productivity

Portable and versatile device

- 1.5 kg single handed device

- ATEX Certified / Intrinsically safe to work safely within hazardous areas