Redefining standards in gas leak inspection

The Ultra Pro hand-held ultrasound imaging camera is capable of accurately locating gas leaks from several meters with unrivaled speed. It excels in finding leaks in high or in hard-to-reach areas.

The sensor works by detecting the specific sounds that pressurized gas leaks emit. Thanks to its integrated 124 ultrasound microphones, the ultrasound camera reconstructs the position of the sound source. The information is overlaid in real-time with a wide angle optical image.

Ultra Pro creates, in a single tap, images and videos that can be assembled in reports either using Distran’s reporting software Audalytics or with the user’s preferred software.

Detects leaks of any gas type:

Working distance from

30 centimeters

or 1 foot

Down to

0.15 L/h

or 0.005 SCFH for a 1.5 bar (22 PSI) gas leak detected at 30 cm distance in a quiet environment

Optical Field of view

> 150°

Acoustic Field of view

180°

Ultra Pro – Ultrasonic leak imaging for high-reliability inspections

Redefining standards in gas leak inspection

The Ultra Pro hand-held ultrasound imaging camera is capable of accurately locating gas leaks from several meters with unrivaled speed. It excels in finding leaks in high or in hard-to-reach areas.

The sensor works by detecting the specific sounds that pressurized gas leaks emit. Thanks to its integrated 124 ultrasound microphones, the ultrasound camera reconstructs the position of the sound source. The information is overlaid in real-time with a wide angle optical image.

Ultra Pro creates, in a single tap, images and videos that can be assembled in reports either using Distran’s reporting software Audalytics or with the user’s preferred software.

Detects leaks of any gas type:

Working distance from

30 centimeters

or 1 foot

Down to

0.15 L/h

or 0.005 SCFH for a 1.5 bar (22 PSI) gas leak detected at 30 cm distance in a quiet environment

Optical Field of view

> 150°

Acoustic Field of view

180°

Acoustic Leak Imaging for Gas Leak Detection

Pinpoint gas leaks without scanning each single element

Acoustic Leak Imaging (ALI) is a technology that allows you to analyse the sound emitted by leaks and and display it as an image. It detects any gas type, even compressed air, vacuum, and steam leaks.

Acoustic Leak Imaging for Gas Leak Detection

Pinpoint gas leaks without scanning each single element

Acoustic Leak Imaging (ALI) is a technology that allows you to analyse the sound emitted by leaks and and display it as an image. It detects any gas type, even compressed air, vacuum, and steam leaks.

Benefits

Why use Ultra Pro?

10 times faster than traditional methods

Classical gas detectors require the operator to thoroughly check every potential leak point. With Acoustic Leak Imaging, detection can be performed without scanning every single element. Inspections are performed meters away, reducing the need for scaffolding.

Quantify leak rate

Ultra Pro provides leak severity and cost in real-time, through leak quantification (in liters per hour, grams per hour or standard cubic feet per hour) without using a tripod. Classify leaks per degree of danger or cost to coordinate maintenance operations.

Uncover leaks in unexpected locations

As sound propagates beyond our line of sight, hidden leaks that are missed with other techniques can be detected with Acoustic Imaging. Leverage Distran cameras' acoustic and optical field of view to survey more at once.

Reduce exposure to gas

Leaks are detected without contact with the gas, at a distance. Operators' exposure to hazardous and toxic gases is greatly reduced.

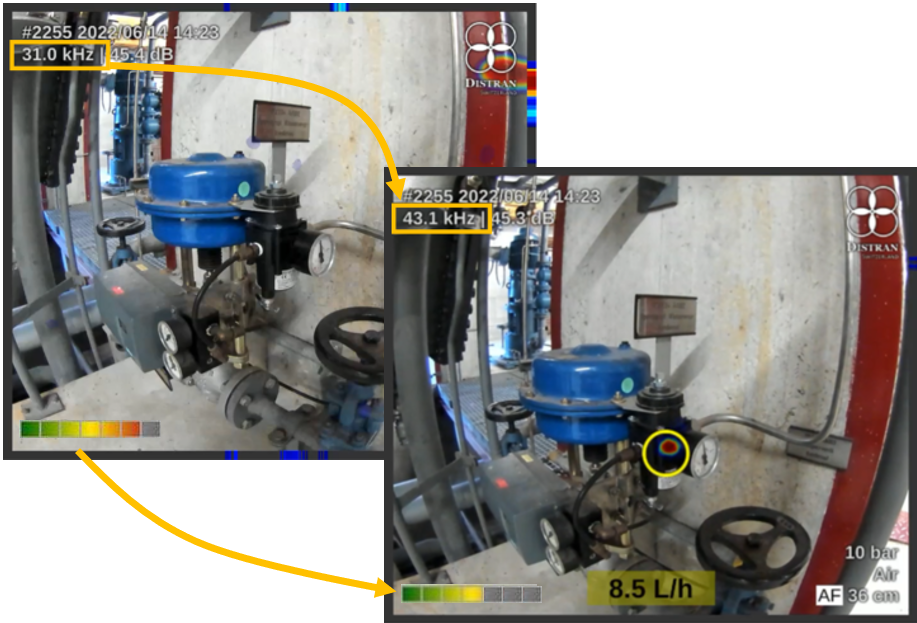

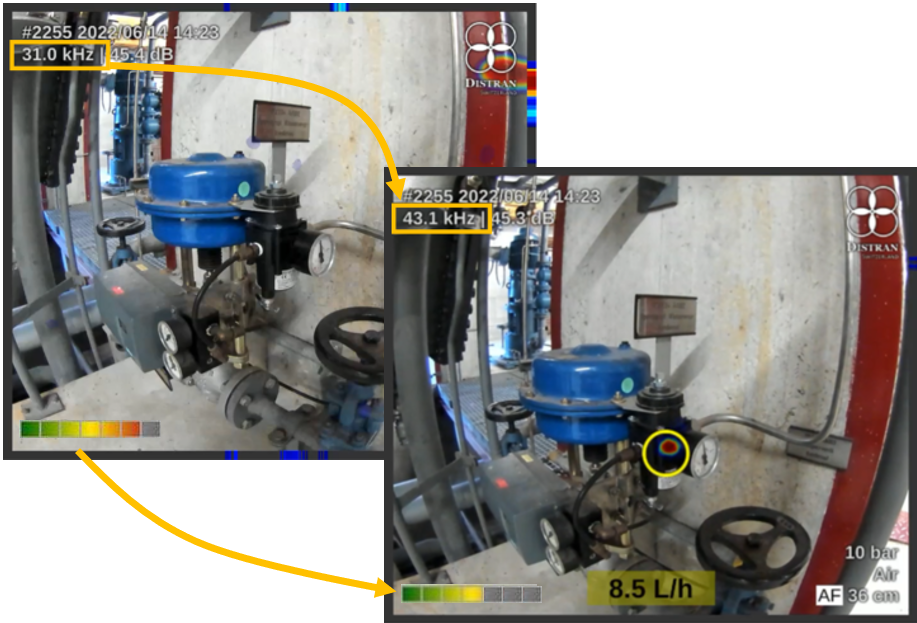

Instantly quantify leak rates and costs to prioritize maintenance

Quantify each leak’s severity and financial impact as you go

Ultra Pro detects and locates leaks but also quantifies the severity of a gas leak in real time without needing a tripod. The leak rate is displayed live (in liters per hour, grams per hour, or standard cubic feet per hour) from the sound source loudness.

The cost of each leak is also displayed on the screen, without external tools or calculations needed. Input the gas type and its unit cost, and the system calculates the annual financial loss based on the measured leak rate and your selected currency.

Leverage these dual insights to classify leaks by order of danger or cost, prioritize maintenance actions, allocate resources efficiently, and support ROI-based decision-making.

Instantly Quantify leak rates and costs to prioritize maintenance

Quantify each leak’s severity and financial impact as you go

Ultra Pro detects and locates leaks but also quantifies the severity of a gas leak in real time without needing a tripod. The leak rate is displayed live (in liters per hour, grams per hour, or standard cubic feet per hour) from the sound source loudness.

The cost of each leak is also displayed on the screen, without external tools or calculations needed. Input the gas type and its unit cost, and the system calculates the annual financial loss based on the measured leak rate and your selected currency.

Leverage these dual insights to classify leaks by order of danger or cost, prioritize maintenance actions, allocate resources efficiently, and support ROI-based decision-making.

Cover more ground in less time and reduce the risk of missed leaks

Widest field of view for more efficient inspections

Ultra Pro combines a 180° acoustic field of view with a >150° optical angle, allowing operators to inspect broader areas in a single passage.

This wide coverage means faster detection and significantly reduced chances of overlooking leaks, especially in broad or complex industrial plants, where large sections must be inspected quickly and thoroughly.

Do you see the second leak that the Distran camera spotted and pinpointed? Expand your field of view and don’t miss leaks.

Cover more ground in less time and reduce the risk of missed leaks

Widest field of view for more efficient inspections

Ultra Pro combines a 180° acoustic field of view with a >150° optical angle, allowing operators to inspect broader areas in a single passage.

This wide coverage means faster detection and significantly reduced chances of overlooking leaks, especially in broad or complex industrial plants, where large sections must be inspected quickly and thoroughly.

Do you see the second leak that the Distran camera spotted and pinpointed? Expand your field of view and don’t miss leaks.

Instant feedback on background noise’s impact

Assess current detection conditions with the Ambient Sound Indicator

The Ambient Sound Indicator is a colored gauge displayed live. It provides operators with instant feedback on ambient ultrasonic noise levels, making them aware of the detection conditions.

- Green means conditions are ideal for detecting even a small leak

- Orange indicates that only larger leaks may be detectable

- Red signals high noise levels; adjustments are required to improve detection

Refer to this indicator to take immediate action to enhance detection conditions, following best practices provided in our training. In this example, the operator would have missed the leak.

Instant feedback on background noise’s impact

Assess current detection conditions with the Ambient Sound Indicator

The Ambient Sound Indicator is a colored gauge displayed live. It provides operators with instant feedback on ambient ultrasonic noise levels, making them aware of the detection conditions.

- Green means conditions are ideal for detecting even a small leak

- Orange indicates that only larger leaks may be detectable

- Red signals high noise levels; adjustments are required to improve detection

Refer to this indicator to take immediate action to enhance detection conditions, following best practices provided in our training. In this example, the operator would have missed the leak.

Locate partial discharges, such as corona, tracking, arcing

Ultra Pro also pinpoints partial discharges and other electrical faults

Partial discharges such as Corona discharges, arcing and tracking happen in high-voltage systems and may lead to failures. These phenomena produce ultrasound and can be precisely localized with Ultra Pro.

Locate partial discharges, such as corona, tracking, arcing

Ultra Pro also pinpoints partial discharges and other electrical faults

Partial discharges such as Corona discharges, arcing and tracking happen in high-voltage systems and may lead to failures. These phenomena produce ultrasound and can be precisely localized with Ultra Pro.

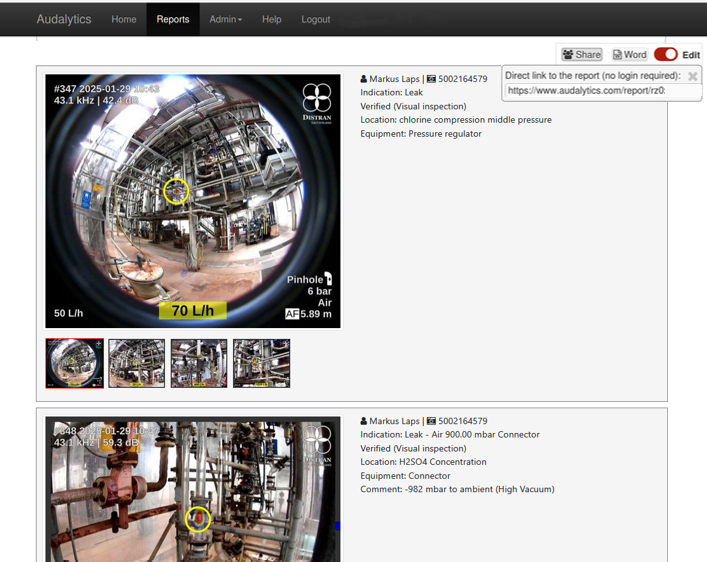

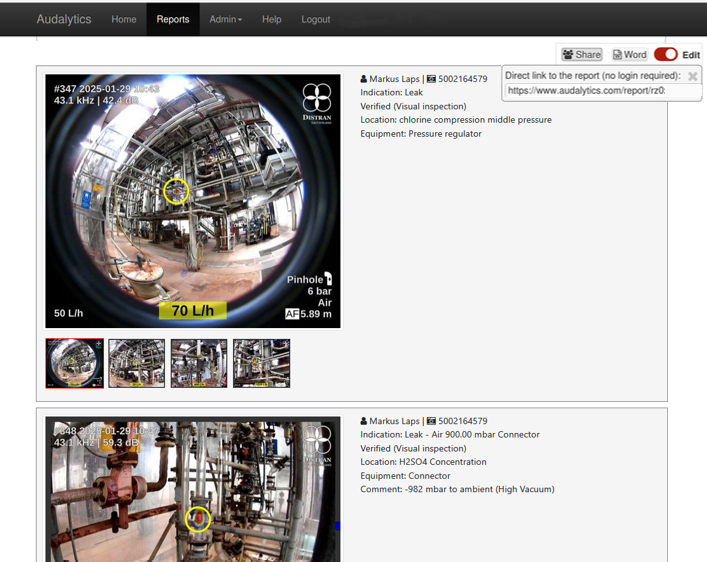

Inspection reports with Audalytics

Get outstanding reports in minutes

Ultrasonic imaging shines in reports because images speak over a thousand words when describing a leak location.

Distran has developed an integrated reporting tool called Audalytics that enables the operator to create a report with annotations within minutes after the inspection. The report can then be shared with all stakeholders without additional software, directly in the browser, where videos are embedded seamlessly.

In one place, structured leak findings and actionable insights to support your operations.

Inspection reports with Audalytics

Get outstanding reports in minutes

Ultrasonic imaging shines in reports because images speak over a thousand words when describing a leak location.

Distran has developed an integrated reporting tool called Audalytics that enables the operator to create a report with annotations within minutes after the inspection. The report can then be shared with all stakeholders without additional software, directly in the browser, where videos are embedded seamlessly.

In one place, structured leak findings and actionable insights to support your operations.

Best ultrasonic camera

Best-in-class handling in the field

From the beginning, Ultra Pro has been developed with industrials and by people who have performed many inspections in the past. Weighing only 1.5 kg including the battery, the camera is operated with a single hand, so that the operator can safely inspect, even in a staircase. The camera has also been tested for drops, in design to be robust. Its integrated LED lighting illuminate dark areas without the need for a separate light source.

1.5 kg all inclusive

Single-handed, self contained

1400 lumens, integrated LED lighting

Robust design

Work safely in hazardous areas

Distran Ultra Pro X is the Ex-proof version, certified under ATEX, IECEx, and UL standards (for use in hazardous locations).

The Distran ultrasound cameras detect leaks of all gases. Being intrinsically safe, Ultra Pro X is specifically designed for use within potentially explosive atmospheres in Oil & Gas, Chemical and Power Generation plants to find leaks of dangerous gases.

Work safely in hazardous areas

Distran Ultra Pro X is the Ex-proof version, certified under ATEX, IECEx, and UL standards (for use in hazardous locations).

The Distran ultrasound cameras detect leaks of all gases. Being intrinsically safe, Ultra Pro X is specifically designed for use within potentially explosive atmospheres in Oil & Gas, Chemical and Power Generation plants to find leaks of dangerous gases.

ULTRA PRO DATA

Technical specifications

| Detected gases | All compressed gases incl. air, vacuum and steam |

| Minimum working distance | 30 centimeters (1 ft) |

| Detection capabilities | 0.15 L/h at 0.3 m (0.005 SCFH at 1 ft) 0.2 L/h at 1 m (0.007 SCFH at 3 ft) 9 L/h at 10 m (0.3 SCFH at 32 ft) For a 1.5 bar (22 PSI) gas leak detected in a quiet environment |

| Acoustic angle of view | 180° |

| Optical angle of view | Fisheye: >150° Wide: 120° |

| Optical zoom | 2X |

| Weight | 1.5 kg (3.3 lb) |

| Battery life | 5 hours (2.5 h x 2 batteries) |

| Ex-Proof option | ATEX: 2014/34/EU IECEx: Ex ic IIC T5 Gc; Ex ic IIIC T100°C Dc UL / CSA: Class I, Division 2, Groups A, B, C, D, T4 KOSHA: 25-KA4BO-0181X; 25-KA4BO-0183X |

| Certifications | RED: 2014/53/EU RoHS: 2011/65/EU WEEE: 2012/19/EU EMC: 2014/30/EU, FCC 47 CFR part 15 B, ICES-003 (UL) Safety: IEC 61010-1 |

| IP Rating | Ultra Pro X: IP54 |

| Operating temperature range | Ultra Pro: -20°C to 50°C (-4°F to 122°F) |

| Integrated LED lights | 1400 lumens |

| Output format | JPEG and AVI |

| Data export | Audalytics or SD card |

| Input methods | Button and touchscreen |

–

Frequently Asked Questions

What distance can a leak be detected?

Depending on the flow rate of the leak, from 30 centimeters (1 feet) to 50-100 meters (150-300 feet). Large leaks (thousand of liters per hour) can be detected up to 50 meters. Small leaks (a few liters per hour) are detectable at a few meters. Typical leak search distance is between 1 to 6 meters (3 to 20 feet).

What type of gases can be detected?

A difference in pressure of 50 mbar (0.7 psi) is recommended for good detection. Below this, it is still be possible to detect gas leaks, but the detection limit of the device is higher. The difference can also be negative (vacuum leaks).

Which gases can be detected ? Does it work with vacuum leaks?

The camera does not detect gases directly but the sound leaks make when the gas is escaping (learn more about technology). Vacuum leaks can also be detected because they create turbulences and thus ultrasounds. What is needed is a minimum pressure difference (typically 50 mbar / 0.7 psi) and a path in the air for the sound to propagate.

Is it possible to operate Ultra Pro in noisy areas (compressor rooms, gas turbine enclosure, etc.)?

Ultra Pro filters all noises outside the detection window, in particular low frequency in the audible range. Even in a very noisy environment like in gas turbine noise enclosure with up to 100 dB(A) noise, leakages have been detected.

Ultra Pro estimates in real-time its lower limit of detection (LoD), allowing the user to know how accurate the inspection is. This is typically useful when acceptance criterion is used.

Can I inspect underground or insulated systems?

Direct sight is not required for leak detection, but the sound must propagate from the leak to the surface of Ultra Pro, where the microphones are located. This is typically not the case for underground systems (shielded by soil). For insulated systems it depends on how tight the insulation is.

What is the accuracy of Ultra Pro?

Similar to an optical camera, the accuracy is determined as an angle (the closer you are to a leak, the smaller is the linear accuracy). The accuracy depends on the acoustic imaging algorithm, the imaging frequency and how good the optical camera and the microphone array are matched.

The typical accuracy is about 1°.

Is the device ATEX Certified / Intrinsically Safe?

Ultra Pro X is the ATEX certified / intrinsically safe version of Ultra Pro. It is certified for zone 2 gas for class IIC (USA: div 2 class 1), including hydrogen.

Does Distran supply a tool to generate digital reports?

Yes. With every device, Distran includes free access to its reporting tool Audalytics. Pictures and videos can be included in reports along with notes and comments. It is easily shared between stakeholders.