Shorter inspection times for longer plant availability

In the age of capacity markets, idle power plants not only lose money due to not selling electricity, but also due to having to pay grid penalties. Often, undetected gas leaks cause the unplanned downtime.

Swift and precise gas leak detection empowers plants to avert unplanned shutdowns and shorten planned outages. To stay online, nuclear, coal-fired, and gas-fired power plants use Distran ultrasonic cameras in many ways:

![]() To detect vacuum and gas leaks of any kind (methane, compressed air, and many more) faster and from safe distances.

To detect vacuum and gas leaks of any kind (methane, compressed air, and many more) faster and from safe distances.

![]() To inspect larger areas in less time including piping systems and pieces of equipment such as turbines, compressors, and condensers in hard-to-access parts of plants.

To inspect larger areas in less time including piping systems and pieces of equipment such as turbines, compressors, and condensers in hard-to-access parts of plants.

![]() To prioritize maintenance activities with Distran’s real-time leak rate quantification and the integrated reporting tool Audalytics.

To prioritize maintenance activities with Distran’s real-time leak rate quantification and the integrated reporting tool Audalytics.

![]() To localize partial discharges.

To localize partial discharges.

Browse the sections below to learn more about how Distran helps streamline electric power generation.

The role of Distran’s acoustic imager to optimize the asset integrity of power plants

Shorter inspection times for longer plant availability

In the age of capacity markets, idle power plants not only lose money due to not selling electricity, but also due to having to pay grid penalties. Often, undetected gas leaks cause the unplanned downtime.

Swift and precise gas leak detection empowers plants to avert unplanned shutdowns and shorten planned outages. To stay online, nuclear, coal-fired, and gas-fired power plants use Distran ultrasonic cameras in many ways:

![]() To detect vacuum and gas leaks of any kind (methane, compressed air, and many more) faster and from safe distances.

To detect vacuum and gas leaks of any kind (methane, compressed air, and many more) faster and from safe distances.

![]() To inspect larger areas in less time including piping systems and pieces of equipment such as turbines, compressors, and condensers in hard-to-access parts of plants.

To inspect larger areas in less time including piping systems and pieces of equipment such as turbines, compressors, and condensers in hard-to-access parts of plants.

![]() To prioritize maintenance activities with Distran’s real-time leak rate quantification and the integrated reporting tool Audalytics.

To prioritize maintenance activities with Distran’s real-time leak rate quantification and the integrated reporting tool Audalytics.

![]() To localize partial discharges.

To localize partial discharges.

Browse the sections below to learn more about how Distran helps streamline electric power generation.

Customer Testimonial from the power generation industry

From fast leak detection to higher plant performance

“Through more efficient detection of leaks, we save effort and ultimately costs, so that the equipment is self-financing after a few months.”

Jörg Schubert, RWE Power AG, Head of Measurement Department

Customer Testimonial from the power generation industry

From fast leak detection to higher plant performance

fast leak detection to higher plant performance

“Through more efficient detection of leaks, we save effort and ultimately costs, so that the equipment is self-financing after a few months.”

Jörg Schubert, RWE Power AG, Head of Measurement Department

6 advantages of using Distran devices for power plant inspections

How does Distran help ensure power plants’ availability?

How does Distran help ensure power plants’ availability?

POWER PLANT SAFETY

Distran ultrasonic cameras do not require contact with the gas. They enable a working distance from 0.3 – 100 m (1 – 330 ft) making scaffolding obsolete.

POWER PLANT UPTIME

As it takes less time to search large areas for gas leaks, scheduled downtime is shorter and unplanned downtime less likely to occur.

EASE OF USE

Our easy-to-use devices don’t require expert know-how. After a short training, new users are all set to start detecting vacuum and gas leaks.

OPTIMIZED MAINTENANCE

The leak rate quantification feature empowers to classify leaks and to prioritize maintenance activities according to the severity of the detected leaks.

ROBUST TO NOISE

Distran’s Acoustic Leak Imaging technology not only enables to detect all types of gas leaks, but also to do so in noisy environments.

MORE THAN LEAKS

In addition to all types of gas leaks, the Ultra Pro and Ultra Pro X can detect partial discharges and other electrical faults.

“Thanks to Distran’s innovative, easy-to-use, and effective technology,

we have already been able to increase the efficiency and safety of our facilities.”

James Barrett, General Manager at Al Ezzel Power Plant, ENGIE

Natural-gas fired, coal-fired, and biofuel-based power plants

An easy-to-use tool for hard-to-reach areas

Power plants based on fossil energy use boilers, turbines, generators, compressors, condensers, and other components connected through piping systems. Undetected gas and vacuum leaks downgrade the performance and availability of equipment often located in hard-to-access and very noisy areas.

Video: Compressed air leak on steam turbine – Leak detected from 15 meters, in a very noisy area >75dB

After a short introduction, operators can detect leaks of any type of gas with the Distran’s Ultra Pro and the ATEX-certified (intrinsically safe) Ultra Pro X; steam and superheated steam leaks on a boiler or a steam turbine, methane leaks on the gas turbine system, compressed air leaks on a steam turbine, hydrogen leaks on the generator, vacuum leaks on condensers, and many more.

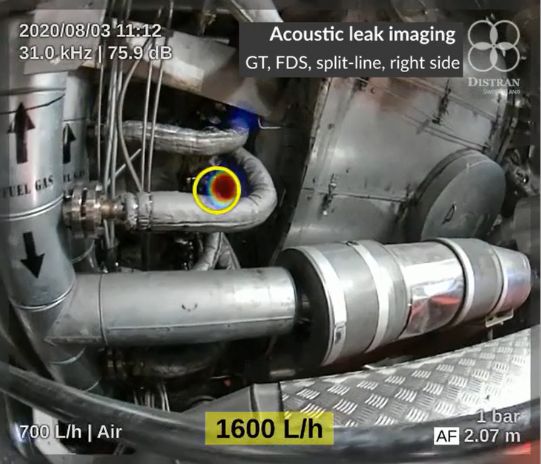

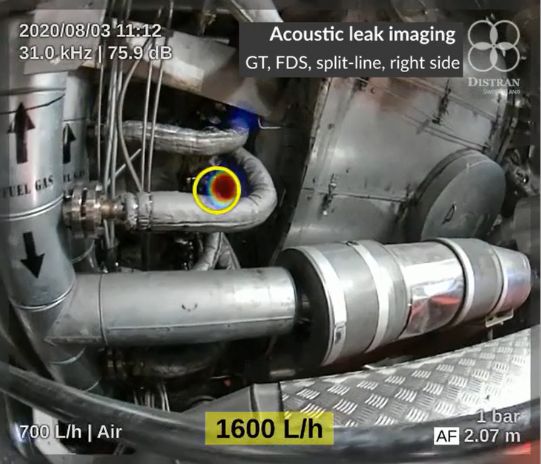

Picture: Methane leak detected in a gas turbine fuel distribution system

Whether it is a conventional coal-fired, a combined cycle power plant (aka CCPP), or another kind of power plant, Distran acoustic cameras support the staff in detecting leaks throughout their facilities faster from safe distances.

Ultimately, our devices prepare the ground to detect leaks under normal operating conditions, and to prioritize maintenance activities during planned outages. It is a power plant efficiency-increasing and safety-enhancing way of gas and vacuum leak detection.

Video: View of a vacuum leak within a CCPP, by the Distran ultrasound camera

Natural-gas fired, coal-fired, and biofuel-based power plants

An easy-to-use tool for hard-to-reach areas

Video: Compressed air leak on steam turbine – Leak detected from 15 meters, in a very noisy area >75dB

Power plants based on fossil energy use boilers, turbines, generators, compressors, condensers, and other components connected through piping systems. Undetected gas and vacuum leaks downgrade the performance and availability of equipment often located in hard-to-access and very noisy areas.

Picture: Methane leak detected in a gas turbine fuel distribution system

After a short introduction, operators can detect leaks of any type of gas with the Distran’s Ultra Pro and the ATEX-certified (intrinsically safe) Ultra Pro X; steam and superheated steam leaks on a boiler or a steam turbine, methane leaks on the gas turbine system, compressed air leaks on a steam turbine, hydrogen leaks on the generator, vacuum leaks on condensers, and many more.

Video: View of a vacuum leak within a CCPP, by the Distran ultrasound camera

Whether it is a conventional coal-fired, a combined cycle power plant (aka CCCP), or another kind of power plant, Distran acoustic cameras support the staff in detecting leaks throughout their facilities faster from safe distances.

Ultimately, our devices prepare the ground to detect leaks under normal operating conditions, and to prioritize maintenance activities during planned outages. It is a power plant efficiency-increasing and safety-enhancing way of gas and vacuum leak detection.

Ensure power plant availability and worker’s safety with Distran Ultra Pro X ultrasonic camera.

Nuclear power plants

A technology to protect people, production, and performance

The proactive detection of malfunctions is a central part of the safety policy at Nuclear Power Plants (NPP) producing low-carbon electricity.

Undetected gas leaks can be an issue in various sections of NPP, i.e., on compressors, valves, turbines, condensers, etc. More and more NPP trust in Distran devices as preventative maintenance tools to detect gas leaks before they become a threat.

Various features of our acoustic cameras such as leak detection from safe distances, or leak rate quantification may be key to preventing shutdowns. Every avoided shutdown of a NPP not only saves money but also reduces CO₂ emissions, as often fossil energy must replace the NPP’s production.

Some NPP also work with Distran to test the tightness of the reactor building. This new application underlines the versatility of our devices to increase both the safety and performance of NPP.

Video: Dry steam leak detected at a distance with Distran Ultra Pro X

Hydrogen leak on alternator

Steam entry on valve

Air ingress on turbine

Nuclear power plants

A technology to protect people, production, and performance

Video: Dry steam leak detected at a distance with Distran Ultra Pro X

The proactive detection of malfunctions is a central part of the safety policy at Nuclear Power Plants (NPP) producing low-carbon electricity.

Undetected gas leaks can be an issue in various sections of NPP, i.e., on compressors, valves, turbines, condensers, etc. More and more NPP trust in Distran devices as preventative maintenance tools to detect gas leaks before they become a threat.

Various features of our acoustic cameras such as leak detection from safe distances, or leak rate quantification may be key to preventing shutdowns. Every avoided shutdown of a NPP not only saves money but also reduces CO₂ emissions, as often fossil energy must replace the NPP’s production.

Some NPP also work with Distran to test the tightness of the reactor building. This new application underlines the versatility of our devices to increase both the safety and performance of NPP.

Hydrogen leak on alternator circuit

Steam entry on valve

Air ingress on turbine

“The unique features of the Distran acoustic camera, in particular the quantification of the leak rate,

empowered us to estimate the degree of urgency for intervention.

In addition to ensuring continuity of supply to the network,

the avoided shutdown would have cost between 5 to 6 million euros per day of shutdown.”

Xavier Bacquenois, Plant Manager – EDF Nuclear Power Plant Dampierre-en-Burly

Partial discharges and other electrical faults

Protection of high-voltage systems

Partial discharges such as corona discharges, arcing, and tracking may occur in high-voltage systems and lead to failures. As these phenomena produce ultrasounds, the portable Distran Ultra Pro is a powerful tool to precisely localize them and help avoid negative consequences.

Picture: Electrical partial discharge detected with Distran Ultra Pro X ultrasound camera

Partial discharges and other electrical faults

Protection of high-voltage systems

Picture: Electrical partial discharge detected with Distran Ultra Pro X ultrasound camera

Partial discharges such as corona discharges, arcing, and tracking may occur in high-voltage systems and lead to failures. As these phenomena produce ultrasounds, the portable Distran Ultra Pro is a powerful tool to precisely localize them and help avoid negative consequences.

–

Contact us

We will be more than happy to advise you on the best solution for your gas leak detection challenges!