27 Sep XERVON: Expanding Services with Acoustic Leak Imaging (ALI) Technology

XERVON Instandhaltung customer success story

Expanding Services with Acoustic Leak Imaging (ALI) Technology

Key facts:

![]() The fast, safe, and reliable detection of all types of gas leaks is a key success factor for XERVON Instandhaltung with industrial customers.

The fast, safe, and reliable detection of all types of gas leaks is a key success factor for XERVON Instandhaltung with industrial customers.

![]() Since 2019, they have been using Distran Ultrasonic Cameras to scan larger plant areas for leaks more quickly.

Since 2019, they have been using Distran Ultrasonic Cameras to scan larger plant areas for leaks more quickly.

![]() The company’s employees benefit from more safety and greater efficiency, while the company benefits from an extended range of services for its customers.

The company’s employees benefit from more safety and greater efficiency, while the company benefits from an extended range of services for its customers.

XERVON Instandhaltung customer success story

Expanding Services with Acoustic Leak Imaging (ALI) Technology

Key facts:

![]() The fast, safe, and reliable detection of all types of gas leaks is a key success factor for XERVON Instandhaltung with industrial customers.

The fast, safe, and reliable detection of all types of gas leaks is a key success factor for XERVON Instandhaltung with industrial customers.

![]() Since 2019, they have been using Distran Ultrasonic Cameras to scan larger plant areas for leaks more quickly.

Since 2019, they have been using Distran Ultrasonic Cameras to scan larger plant areas for leaks more quickly.

![]() The company’s employees benefit from more safety and greater efficiency, while the company benefits from an extended range of services for its customers.

The company’s employees benefit from more safety and greater efficiency, while the company benefits from an extended range of services for its customers.

For more than 50 years, XERVON Instandhaltung has been offering a comprehensive package of services to companies in the process industry. Highly qualified specialists offer their expertise in maintenance, turnaround management, and infrastructure services to companies in the petrochemical, oil and gas, and many other industries. The fast and safe detection of leaks in plants and chemical parks plays a central role.

“Fast and reliable detection of gas leaks is a key factor in enabling our customers to operate their facilities economically, sustainably, and safely.”

Steven Nagel

Technical Site Manager

XERVON Instandhaltung

Fewer leaks with less effort?

In the worst case, undetected gas leaks can shut down entire chemical plants and endanger the safety of personnel. For XERVON Instandhaltung, the timely detection of gas leaks has always been of critical importance, both as a preventive routine activity and as part of legally required inspections.

In the past, the detection and repair of gas leaks led to high costs, as they required scaffolding and interruptions in operations to soap up entire plants. Therefore, starting in 2019, XERVON Instandhaltung has been looking for modern approaches that meet various requirements:

EFFICIENCY

Detecting gas leaks should take as little time and money as possible and avoid interrupting operations.

SAFETY

Especially when dealing with hazardous gases, the new method should protect the personnel involved.

VERSATILITY

Leak detection for all types of gases should become easier to perform.

During the evaluation, Distran Ultra Pro X came out on top. Today, XERVON Instandhaltung uses several ultrasonic cameras in rotation at different locations.

Employees trained in one day use the equipment for various inspections, including compressed air, hydrogen, and vacuum applications.

“Since 2019, we have been detecting leaks of all gas types with the Distran Ultra Pro X.

Thanks to the simple and reliable handling, even new employees quickly become familiar with the Distran Ultra Pro X. Compared to traditional methods, we can search larger areas faster – without scaffolding and without interrupting operations.”

Steven Nagel, Technical Site Manager, XERVON Instandhaltung

Greater safety for all

Leak detection inspections often take place in hazardous areas of plants and chemical parks and involve pipes containing dangerous gases such as hydrogen. The use of the ATEX–certified (intrinsically safe) Distran Ultra Pro X simplifies the tasks of the personnel and increases their safety:

- Small leaks of all types of gases can be detected from a safe distance.

- Since the camera detects leaks based on ultrasound (Acoustic Leak Imaging), ambient noise does not affect the leak detection.

- The Distran Ultra Pro X calculates not only the location of the leak, but also the leak rate – whether the leak source is a flange, valve, weld, etc.

Detect small leaks even in noisy areas

Real-time leak-rate quantification

Detect gas leaks at a safe distance

The quantified leak rates as well as all other relevant data (images, videos, etc.) can be found in the integrated reporting tool to improve the planning and prioritization of any maintenance work.

XERVON Instandhaltung also benefits from Distran in this area: if the inspection and maintenance of a 10 m high tank used to take weeks, it now takes 1-2 days with Distran Ultra Pro X.

“Thanks to Distran, our people work faster and safer. In addition, the Acoustic Leak Imaging technology saves us money because it takes less time, manpower, and material to detect leaks. Overall, we have been able to expand our offering as an industrial service provider. This has been well received by our customers – and has resulted in new business.”

Steven Nagel, Technical Site Manager, XERVON Instandhaltung

Leak detection leads to more new business

In addition to its business significance, the Distran Ultra Pro X is first and foremost an excellent new tool for the XERVON Instandhaltung staff, making their daily work more efficient and safer:

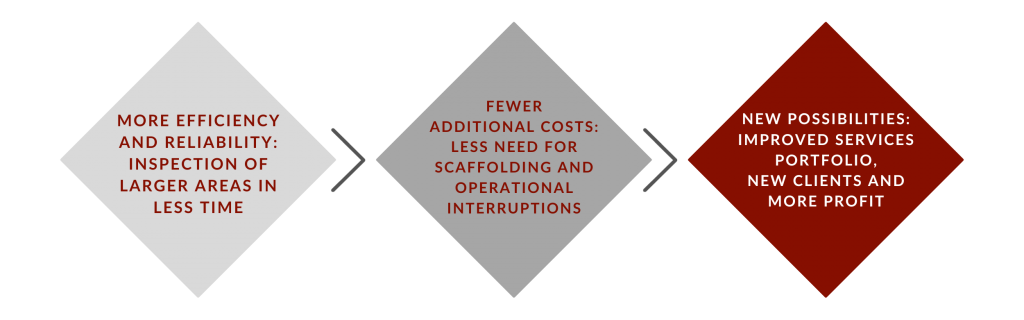

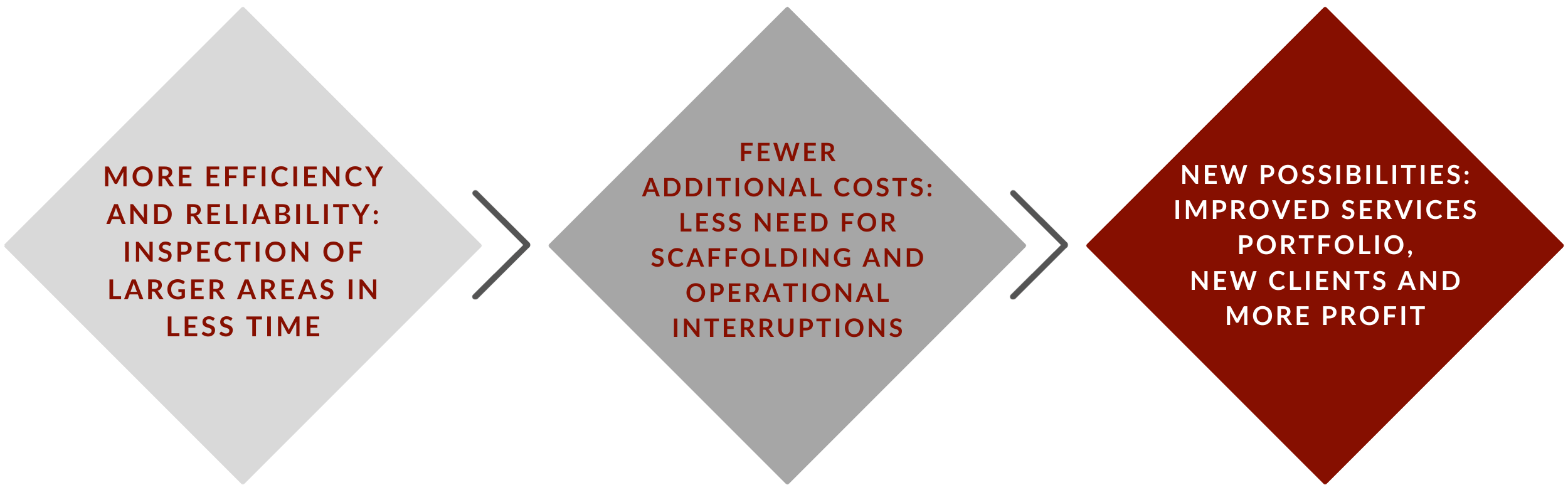

- With the ultrasonic camera, they are able to search larger areas of the plant for leaks in a much shorter time.

- There are fewer additional costs for inspections, such as lifting equipment, interruptions to operations, etc.

- Staff is better protected from hazardous gases because Distran Ultra Pro X detects leaks from a safe distance.

For XERVON Instandhaltung as a company, the use of the new technology is a key success factor.

With the introduction of the new technology, the industrial service provider has been able to expand its offering to include a comprehensive leak detection service. The sharpened profile has generated a lot of new business.

The customers of XERVON Instandhaltung appreciate the use of Distran ultrasonic cameras in their plants, as they also benefit from the faster, safer, and more reliable detection of gas leaks.

In case you want to learn more about how to improve gas leak detection and your service quality, talk to the Distran expert in your region.