11 Jun What are “ghosts” or artifacts when using an ultrasound camera and how to avoid them?

Understanding false signals and their impact on leak detection accuracy

What are “ghosts” or artifacts when using an ultrasound camera and how to avoid them?

Acoustic imaging has become widespread in industry for detecting gas leaks or other defects (partial discharges, mechanical wear and tear). It functions by capturing sound waves produced by defects or leaks. Unlike gas detectors that are sensitive to a specific gas (or class of gases), acoustic imaging detects sound sources.

In addition to gas leaks, other phenomena can also emit ultrasounds that are detectable by the camera. These include flow noise in pipes or cavitation, often occurring at pipe angles or downstream from pressure regulators. Echoes, caused by sound reflecting off nearby surfaces, represent another type of source. Trained operators can distinguish these from real leak indications and even use them to trace leaks hidden in areas that are not directly visible.

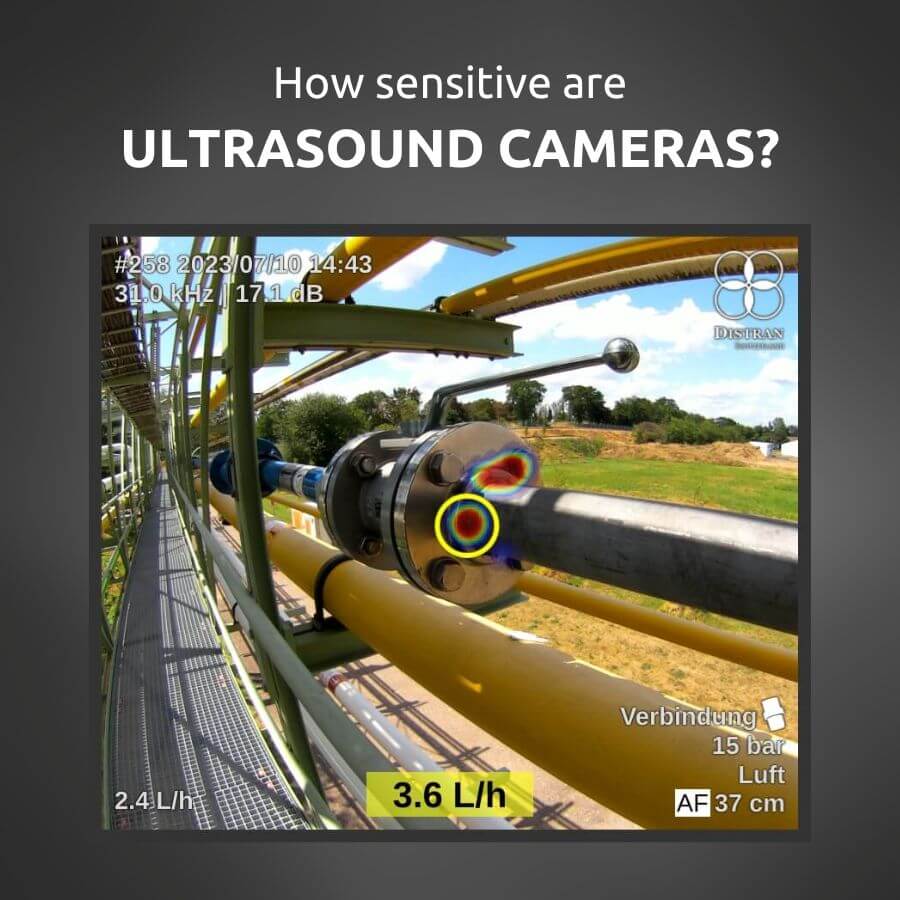

On the left, an image from the Distran Ultra Pro camera showing the detection of a compressed air leak on an actuator, visible inside the yellow track. In addition to the main leak, the camera also detects an acoustic echo on the duct behind, caused by the leak’s sound reflecting off the flat surface.

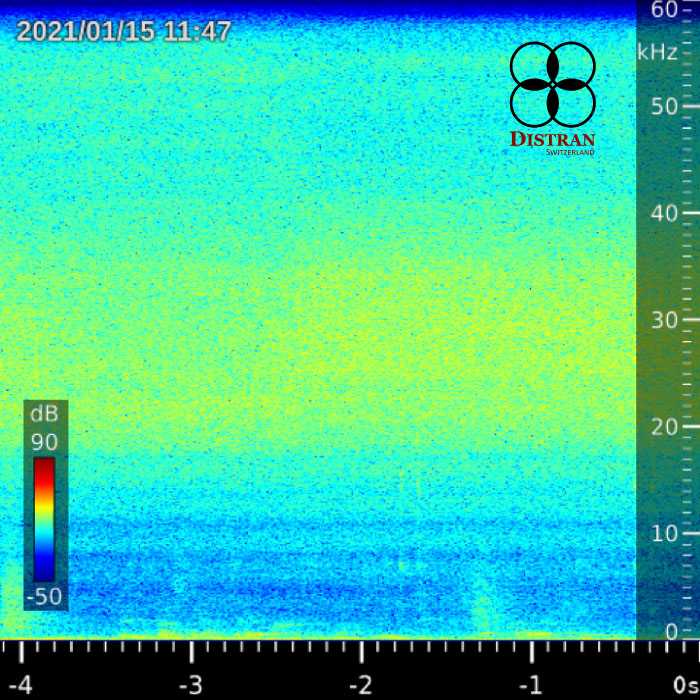

On the right, we see typical flow noise along a pipe. Unlike a gas leak, which typically produces a stationary acoustic source, the sound pattern here follows the path of the flowing medium—indicating it’s due to normal flow rather than a leak.

Understanding false signals and their impact on leak detection accuracy

What are “ghosts” or artifacts when using an ultrasound camera and how to avoid them?

Acoustic imaging has become widespread in industry for detecting gas leaks or other defects (partial discharges, mechanical wear and tear). It functions by capturing sound waves produced by defects or leaks. Unlike gas detectors that are sensitive to a specific gas (or class of gases), acoustic imaging detects sound sources.

In addition to gas leaks, other phenomena can also emit ultrasounds that are detectable by the camera. These include flow noise in pipes or cavitation, often occurring at pipe angles or downstream from pressure regulators. Echoes, caused by sound reflecting off nearby surfaces, represent another type of source. Trained operators can distinguish these from real leak indications and even use them to trace leaks hidden in areas that are not directly visible.

On the left, an image from the Distran Ultra Pro camera showing the detection of a compressed air leak on an actuator, visible inside the yellow track. In addition to the main leak, the camera also detects an acoustic echo on the duct behind, caused by the leak’s sound reflecting off the flat surface.

On the right, we see typical flow noise along a pipe. Unlike a gas leak, which typically produces a stationary acoustic source, the sound pattern here follows the path of the flowing medium—indicating it’s due to normal flow rather than a leak.

“Ghosts” and their origin

Some acoustic cameras suffer from artifacts or colloquially named “ghosts”. These artifacts are sound sources that are entirely artificial – created by the camera’s internal signal processing.

These artifacts are purely mathematical, created from signal processing algorithms and don’t correspond to any physical sound in the environment being inspected. They primarily stem from two sources: inadequate microphone array geometry (for the frequency being imaged, also called aliasing) and/or the acoustic imaging algorithm used along with its settings.

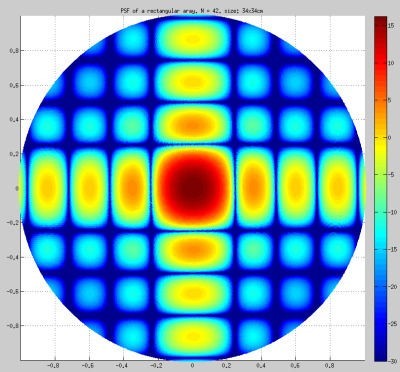

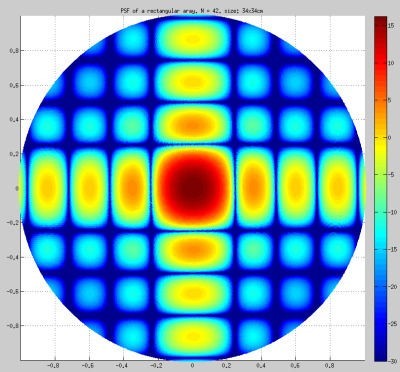

When a single sound source is present, the acoustic camera’s response isn’t a simple point on the acoustic image. Instead, as shown in the image, a complete pattern appears, also called the point spread function (PSF) of the microphone array. This PSF depends on the geometry and number of microphones in the array. The sources (particularly sidelobes) may remain visible in the final image, appearing as ghost-like indications surrounding the true source.

Angular Point Spread Function of a rectangular array of 42 microphones. The main blob (or lobe) indicates the direction of the sound source, with visible sidelobes approximately 10 dB lower than the main lobe. The difference between the maximum of the main lobe and the highest side lobe is often referred to as dynamic range.

“Ghosts” and their origin

Some acoustic cameras suffer from artifacts or colloquially named “ghosts”. These artifacts are sound sources that are entirely artificial – created by the camera’s internal signal processing.

These artifacts are purely mathematical, created from signal processing algorithms and don’t correspond to any physical sound in the environment being inspected. They primarily stem from two sources: inadequate microphone array geometry (for the frequency being imaged, also called aliasing) and/or the acoustic imaging algorithm used along with its settings.

When a single sound source is present, the acoustic camera’s response isn’t a simple point on the acoustic image. Instead, as shown in the image, a complete pattern appears, also called the point spread function (PSF) of the microphone array. This PSF depends on the geometry and number of microphones in the array. The sources (particularly sidelobes) may remain visible in the final image, appearing as ghost-like indications surrounding the true source.

Angular Point Spread Function of a rectangular array of 42 microphones. The main blob (or lobe) indicates the direction of the sound source, with visible sidelobes approximately 10 dB lower than the main lobe. The difference between the maximum of the main lobe and the highest side lobe is often referred to as dynamic range.

Side lobes are typically removed from the final image by thresholding (removing all sources below a certain level, such as 10dB below the main source). However, when multiple sound sources are present, the PSFs of each source interfere, creating a sum of sidelobes that become difficult to eliminate. These appear in the final image, creating these “ghosts” or artifacts, that don’t represent actual real sound sources, as shown in the image below.

Since these “ghosts” depend on the position of sound sources in the environment, they make inspections difficult in typical industrial settings, particularly when searching for small to medium-sized gas leaks.

Picture (from a power plant inspection) from an ultrasound camera suffering from mathematical artifacts (“ghosts”) that manifest as an arc-shaped pattern that does not correspond to real physical sources. These processing artifacts create challenges for operators because they can appear in locations where genuine gas leaks commonly occur, potentially masking real issues or leading to false positives

”Ghosts” on another ultrasound camera susceptible to artifacts. None of the sources on the right of the image are real ones but results from mathematical effects of the imaging algorithm.

Side lobes are typically removed from the final image by thresholding (removing all sources below a certain level, such as 10dB below the main source). However, when multiple sound sources are present, the PSFs of each source interfere, creating a sum of sidelobes that become difficult to eliminate. These appear in the final image, creating these “ghosts” or artifacts, that don’t represent actual real sound sources, as shown in the image below.

Since these “ghosts” depend on the position of sound sources in the environment, they make inspections difficult in typical industrial settings, particularly when searching for small to medium-sized gas leaks.

Picture (from a power plant inspection) from an ultrasound camera suffering from mathematical artifacts (“ghosts”) that manifest as an arc-shaped pattern that does not correspond to real physical sources. These processing artifacts create challenges for operators because they can appear in locations where genuine gas leaks commonly occur, potentially masking real issues or leading to false positives

”Ghosts” on another ultrasound camera susceptible to artifacts. None of the sources on the right of the image are real ones but results from mathematical effects of the imaging algorithm.

Distran’s cameras incorporate multiple advanced acoustic imaging algorithms designed to minimize the appearance of artifacts in the image. In addition, the computer-optimized array geometry ensures optimal imaging performance across all frequencies. This gives operators confidence that what they see on the screen corresponds to real sound sources. In noisy environments, camera reliability is crucial for detecting small leaks. Furthermore, it also reduces the required operator training and increases the reproducibility of leak inspection campaigns: the more complex and cumbersome a device is to operate, the higher the likelihood of errors and discrepancies between different operators’ inspection results.

Distran’s cameras incorporate multiple advanced acoustic imaging algorithms designed to minimize the appearance of artifacts in the image. In addition, the computer-optimized array geometry ensures optimal imaging performance across all frequencies. This gives operators confidence that what they see on the screen corresponds to real sound sources. In noisy environments, camera reliability is crucial for detecting small leaks. Furthermore, it also reduces the required operator training and increases the reproducibility of leak inspection campaigns: the more complex and cumbersome a device is to operate, the higher the likelihood of errors and discrepancies between different operators’ inspection results.

Conclusion

While environmental ultrasound sources (such as gas leaks, flow noise, and cavitation) and echoes are legitimate acoustic phenomena detected by an acoustic camera, “ghosts” or artifacts can also appear in some acoustic camera images. These artifacts make it challenging, even for trained operators, to detect medium to small leaks in real industrial environments, as they often appear as false positives, creating confusing moving indications on the acoustic image. As a result, smaller leaks, or leaks at unexpected locations (i.e. at heights, or close to the ground) may be overlooked.

To perform reliable inspections in real, noisy, industrial environments, operators must choose an acoustic camera that incorporates proper signal processing and proper microphone array geometry that avoids displaying artifacts. Distran cameras, such as Ultra Pro and Ultra Pro X incorporate computer optimized array geometry and algorithms to reduce, if not eliminate, these artifacts, providing excellent performance in noisy environments, such as refinery units, machinery halls, etc. where not missing a leak is critical.

Conclusion

While environmental ultrasound sources (such as gas leaks, flow noise, and cavitation) and echoes are legitimate acoustic phenomena detected by an acoustic camera, “ghosts” or artifacts can also appear in some acoustic camera images. These artifacts make it challenging, even for trained operators, to detect medium to small leaks in real industrial environments, as they often appear as false positives, creating confusing moving indications on the acoustic image. As a result, smaller leaks, or leaks at unexpected locations (i.e. at heights, or close to the ground) may be overlooked.

To perform reliable inspections in real, noisy, industrial environments, operators must choose an acoustic camera that incorporates proper signal processing and proper microphone array geometry that avoids displaying artifacts. Distran cameras, such as Ultra Pro and Ultra Pro X incorporate computer optimized array geometry and algorithms to reduce, if not eliminate, these artifacts, providing excellent performance in noisy environments, such as refinery units, machinery halls, etc. where not missing a leak is critical.

Florian Perrodin

Florian Perrodin is CEO of Distran, a Swiss company that developed the world’s first ultrasound camera for gas leak detection. With an engineering background, Florian leads the company’s efforts to help industrial clients reduce greenhouse emissions, improve safety and operational reliability. Distran serves oil and gas, chemical, power generation, and manufacturing companies globally through offices in Switzerland, the US, Middle East, Europe, India, and Singapore.

Florian Perrodin

Florian Perrodin is CEO of Distran, a Swiss company that developed the world’s first ultrasound camera for gas leak detection. With an engineering background, Florian leads the company’s efforts to help industrial clients reduce greenhouse emissions, improve safety and operational reliability. Distran serves oil and gas, chemical, power generation, and manufacturing companies globally through offices in Switzerland, the US, Middle East, Europe, India, and Singapore.