23 May Score Group: How one operator tackled offshore platform critical gas turbine failure with Ultra Pro

Score Success Story

How one operator tackled offshore platform critical gas turbine failure with Ultra Pro

In the high-stakes world of offshore operations, power turbines’ uptime isn’t just a metric—it’s a mission.

When a gas turbine repeatedly tripped offline, it wasn’t just a minor inconvenience. It impacted the primary driver of the onboard power generation system, plant safety systems, and the overall plant uptime.

The root cause? A suspected hot air leak, elevating temperatures inside the turbine enclosure, triggering ambient sensors, causing emergency shutdowns.

Score Success Story

How one operator tackled offshore platform critical gas turbine failure with Ultra Pro

In the high-stakes world of offshore operations, power turbines’ uptime isn’t just a metric—it’s a mission.

When a gas turbine repeatedly tripped offline, it wasn’t just a minor inconvenience. It impacted the primary driver of the onboard power generation system, plant safety systems, and the overall plant uptime.

The root cause? A suspected hot air leak, elevating temperatures inside the turbine enclosure, triggering ambient sensors, causing emergency shutdowns.

A mystery inside the enclosure

Despite recognizing the symptoms, conventional inspection methods failed to identify the exact locations due to:

- High ambient noise levels interfere with their on-hand detection tools

- Limited safe access to the high-temperature enclosure

- Risk to personnel safety during extended inspections

- Inability to visually confirm leak sources

The client needed to know exactly where the hot air was escaping—without dismantling the enclosure or putting personnel at risk.

Armed with deep operational expertise and an urgency to restore production, the operations management team turned to a trusted partner for help: Score Group. Known for its emissions mitigation capabilities, Score brought its experience and a key asset in their toolkit —the Ultra Pro ultrasound camera from Distran.

This story is about how combining the right technology and expertise overcame an elusive problem and brought a critical turbine back online.

Score Group, a D2Zero company, is a global provider of advanced engineering technology services specializing in valve and emissions management, gas turbines, and surface technologies.

With over 40 years of experience, Score serves various sectors, including oil and gas, energy, defense, and aerospace. Headquartered in Scotland, the company employs over 1,000 professionals worldwide. In the oil and gas industry, Score Group offers comprehensive services to help their clients maintain efficiency, safety, and regulatory compliance.

Their expertise ensures operational efficiency and safety for clients across the globe.

Score Group, a D2Zero company, is a global provider of advanced engineering technology services specializing in valve and emissions management, gas turbines, and surface technologies.

With over 40 years of experience, Score serves various sectors, including oil and gas, energy, defense, and aerospace. Headquartered in Scotland, the company employs over 1,000 professionals worldwide. In the oil and gas industry, Score Group offers comprehensive services to help their clients maintain efficiency, safety, and regulatory compliance.

Their expertise ensures operational efficiency and safety for clients across the globe.

Score brings clarity with Distran’s Ultra Pro

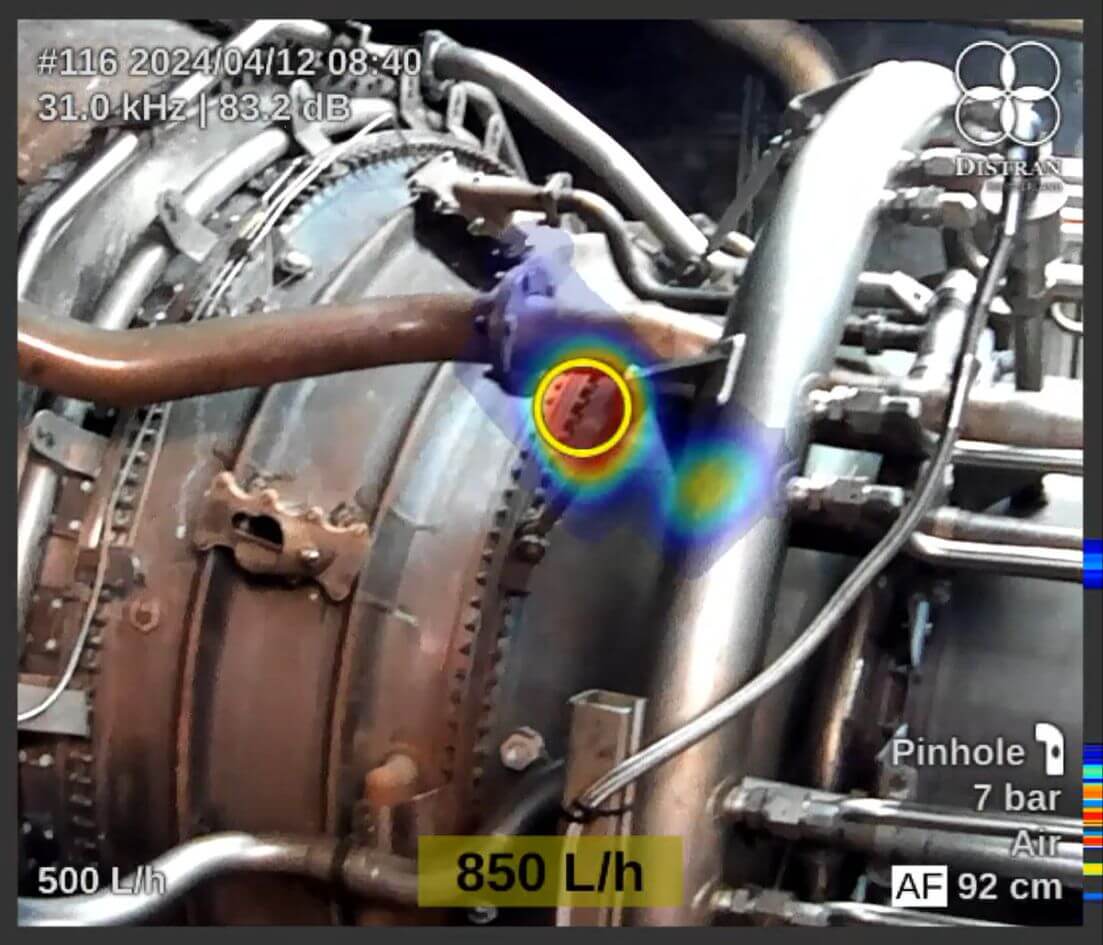

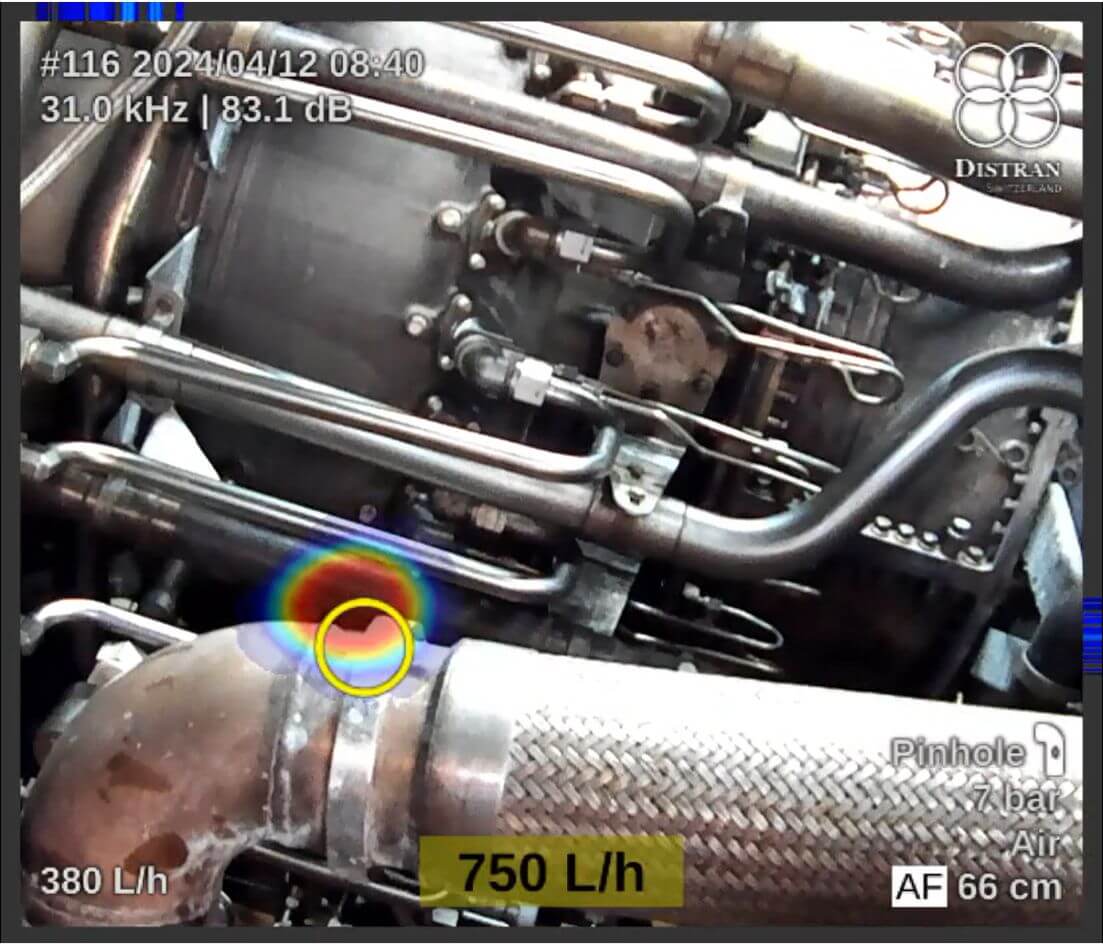

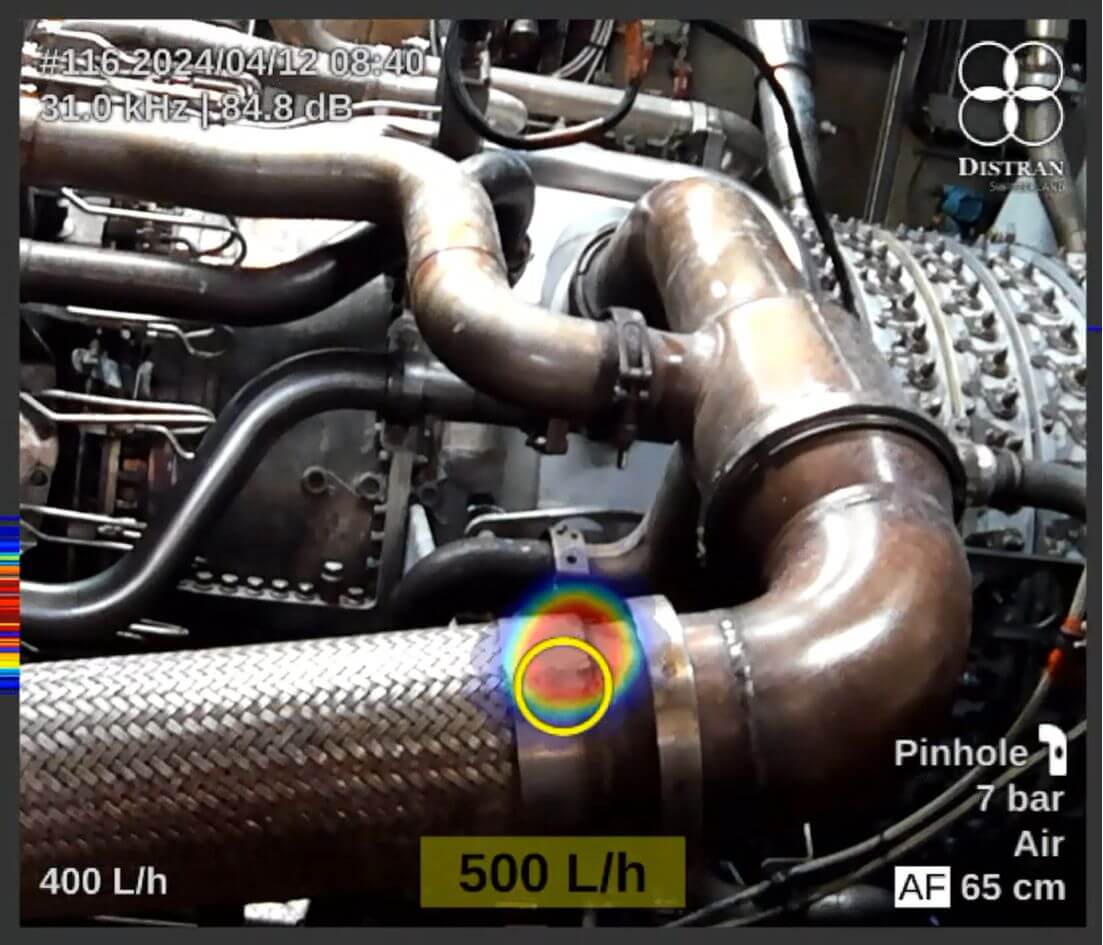

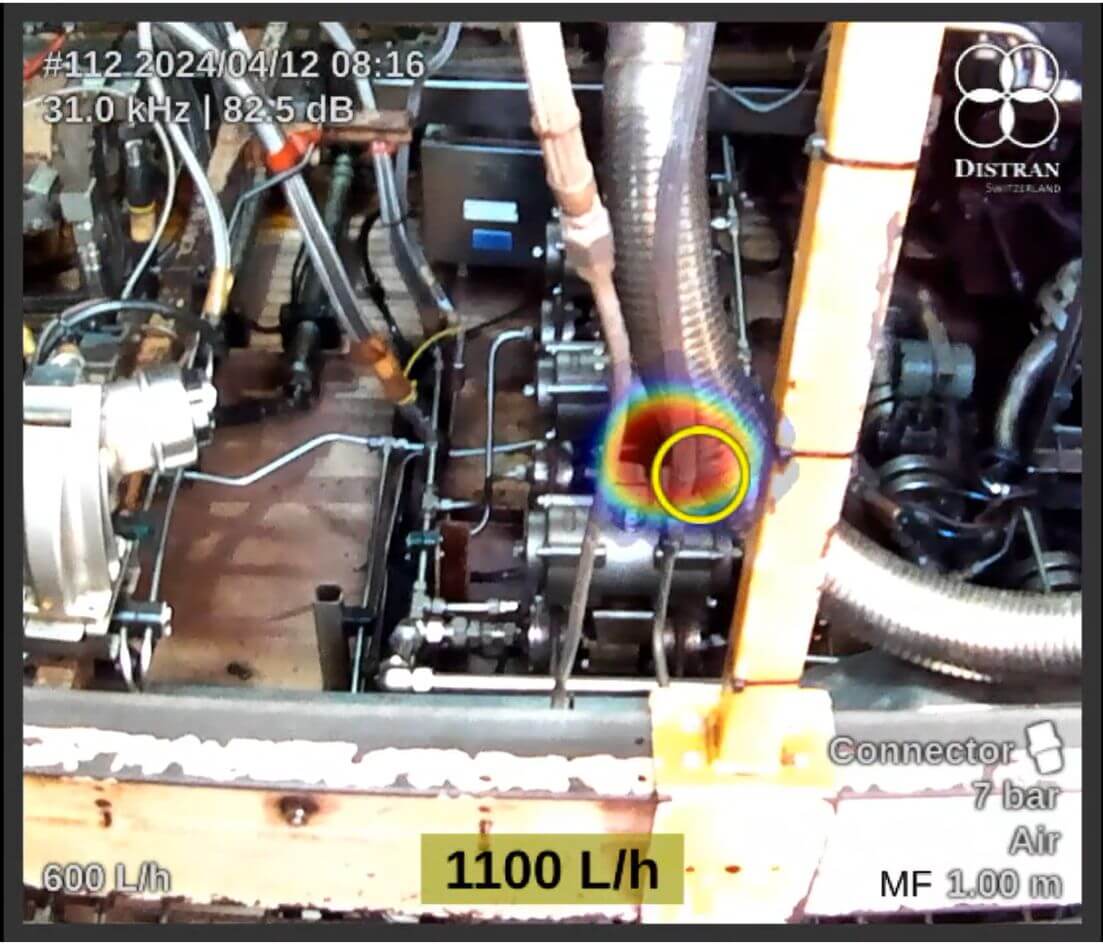

For this mission, Score’s engineers trusted the Distran Ultra Pro, the state-of-the-art ultrasonic camera capable of detecting gas and air leaks even in extremely noisy industrial settings. Unlike traditional tools that require close proximity and controlled conditions, the Ultra Pro filters out competing background noise and visualizes leaks as live acoustic images. This meant Score could survey the turbine from a safe distance—without interrupting operations or breaching the enclosure.

In just one survey session, three distinct air leaks were detected around the bellows pipes. The acoustic signatures were clear and unambiguous, even amid the turbine’s ambient roar. For the first time, the client had concrete, visual evidence of the problem areas.

The Ultra Pro offered critical advantages for this offshore application:

- Remote detection capability allowing safe operation from a distance

- Advanced noise filtering to isolate leak sounds from turbine ambient noise

- Real-time visualization of leaks as they occurred

- Non-intrusive inspection without disrupting ongoing operations

Score brings clarity with Distran’s Ultra Pro

For this mission, Score’s engineers trusted the Distran Ultra Pro, the state-of-the-art ultrasonic camera capable of detecting gas and air leaks even in extremely noisy industrial settings. Unlike traditional tools that require close proximity and controlled conditions, the Ultra Pro filters out competing background noise and visualizes leaks as live acoustic images. This meant Score could survey the turbine from a safe distance—without interrupting operations or breaching the enclosure.

In just one survey session, three distinct air leaks were detected around the bellows pipes. The acoustic signatures were clear and unambiguous, even amid the turbine’s ambient roar. For the first time, the client had concrete, visual evidence of the problem areas.

The Ultra Pro offered critical advantages for this offshore application:

- Remote detection capability allowing safe operation from a distance

- Advanced noise filtering to isolate leak sounds from turbine ambient noise

- Real-time visualization of leaks as they occurred

- Non-intrusive inspection without disrupting ongoing operations

“Thanks to Score’s expertise and technology,

we were able to quickly identify and resolve these critical air leaks

that had been causing our turbine to trip.

Our turbine is now running at full efficiency.”

Platform Operations Technician

Ready to empower your team with acoustic imaging built for gas turbines?

Precision repairs, maximum impact on reliability and confidence

With the leaks identified, the asset team could plan precise maintenance interventions. No guesswork. No exploratory downtime. Technicians accessed the specific areas and sealed the damaged components, restoring the enclosure’s integrity.

After completing repairs, Score returned for a follow-up inspection using the Ultra Pro. This time, the scan revealed a minor leak that the initial, more significant leaks had previously masked, prompting a second corrective action.

A final survey confirmed it: the turbine was now fully sealed. No leaks. No temperature surges. No more unexpected shutdowns.

Post-repair, the turbine returned to full operational duty. Temperatures within the enclosure remained stable and well within safety parameters. The shutdown triggers were no longer activated. Production resumed at full capacity.

Immediate and measurable benefits:

Restored Operational Reliability

The turbine returned to full operational duty with no further trips.

Stabilized Enclosure Temperatures

Readings remained well within safety parameters.

Enhanced safety

Enclosure temperatures stabilized within safety limits, mitigating potential risks from hot air leaks.

Eliminated Production Losses

Power generation capacity was fully restored.

Reduced Emissions

Unintended gas releases were eliminated.

Precision repairs, maximum impact on reliability and confidence

With the leaks identified, the asset team could plan precise maintenance interventions. No guesswork. No exploratory downtime. Technicians accessed the specific areas and sealed the damaged components, restoring the enclosure’s integrity.

After completing repairs, Score returned for a follow-up inspection using the Ultra Pro. This time, the scan revealed a minor leak that the initial, more significant leaks had previously masked, prompting a second corrective action.

A final survey confirmed it: the turbine was now fully sealed. No leaks. No temperature surges. No more unexpected shutdowns.

Post-repair, the turbine returned to full operational duty. Temperatures within the enclosure remained stable and well within safety parameters. The shutdown triggers were no longer activated. Production resumed at full capacity.

Immediate and measurable benefits:

Restored Operational Reliability

The turbine returned to full operational duty with no further trips.

Stabilized Enclosure Temperatures

Readings remained well within safety parameters.

Enhanced safety

Enclosure temperatures stabilized within safety limits, mitigating potential risks from hot air leaks.

Eliminated Production Losses

Power generation capacity was fully restored.

Reduced Emissions

Unintended gas releases were eliminated.

Ultra Pro was a Game-Changer

Three key reasons why Distran Ultra Pro made the difference:

Unmatched sensitivity

in noisy environments

Traditional detectors can’t handle the ambient noise around turbines. The Ultra Pro’s sensitive acoustic detection capabilities honed in on the precise location of multiple leaks at once.

Fast visual diagnosis

confirmation

The team didn’t just “think” they found the leaks—they saw them. The acoustic imaging device provided instant confirmation, clarity, and leak rate data.

Enhanced safety

through remote operation

The maintenance and operations team members avoided risky entry into a hot enclosure. The handheld camera enabled full surveys from a safe distance, minimizing exposure and downtime.

Why Score Group relies on Ultra Pro

An important tool in our emissions elimination toolkit

“The Ultra Pro ultrasound camera has become an important tool in our emissions elimination toolkit, especially where safety and efficiency are paramount. Its ability to cut through the intense background noise of a functioning turbine while providing crystal-clear visualization of even minor leaks has enhanced our leak detection capabilities.

For our clients operating in demanding environments, this technology represents not just a maintenance enhancement but a critical asset protection solution.”

Aidan Glennie, Emissions Elimination Survey Technician

– Score Group

A Partnership Built on Precision

The success of this operation was the result of a collaborative mindset. The client drove the urgency, stayed engaged at every stage, and made quick, informed decisions. Score Group brought their field-tested expertise and their deep understanding of emissions diagnostics. And Distran provided the technology that enabled it all.