03 Sep Operations Manager balances safety and economics in a global provider of industrial gases

Real World Stories: Chemical Industry

Operations Manager balances safety and economics in a global provider of industrial gases

Highlights:

![]() Integrating the Distran ultrasonic camera cuts inspection time and commissioning by a day, leading to significant cost savings.

Integrating the Distran ultrasonic camera cuts inspection time and commissioning by a day, leading to significant cost savings.

![]() Proactive leak detection with Ultra Pro allows early detection of hazardous gas leaks without requiring expert knowledge, ensuring safe and reliable operations.

Proactive leak detection with Ultra Pro allows early detection of hazardous gas leaks without requiring expert knowledge, ensuring safe and reliable operations.

![]() The leak quantification feature, combined with enhanced inspection reports, streamlined the maintenance processes.

The leak quantification feature, combined with enhanced inspection reports, streamlined the maintenance processes.

Real World Stories: Chemical Industry

Operations Manager balances safety and economics in a global provider of industrial gases

Highlights:

![]() Integrating the Distran ultrasonic camera cuts inspection time and commissioning by a day, leading to significant cost savings.

Integrating the Distran ultrasonic camera cuts inspection time and commissioning by a day, leading to significant cost savings.

![]() Proactive leak detection with Ultra Pro allows early detection of hazardous gas leaks without requiring expert knowledge, ensuring safe and reliable operations.

Proactive leak detection with Ultra Pro allows early detection of hazardous gas leaks without requiring expert knowledge, ensuring safe and reliable operations.

![]() The leak quantification feature, combined with enhanced inspection reports, streamlined the maintenance processes.

The leak quantification feature, combined with enhanced inspection reports, streamlined the maintenance processes.

A global provider of industrial gases and engineering services operates a plant that produces carbon monoxide and hydrogen, mainly for companies operating in the surrounding chemical park. They focus on developing and producing crop protection products, polymers, plastics, and rubbers. The gases are mainly transported via pipelines. The fast, safe, and reliable detection of gas leaks is crucial here.

The plant’s operations manager fully appreciates the importance of proactive leak detection, mainly when dealing with hazardous gases. He constantly seeks new ways to optimize personnel safety and ensure orderly operations.

Proactive leak detection with advanced technology

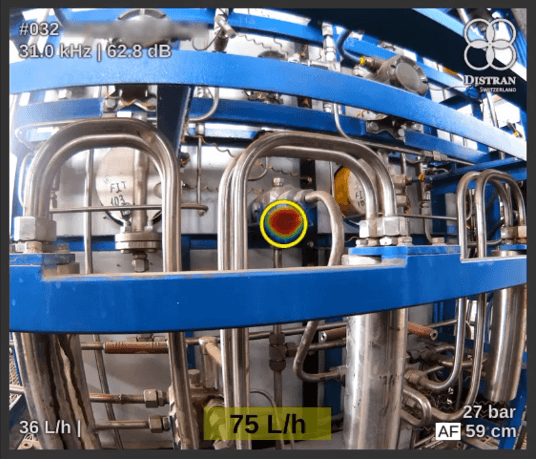

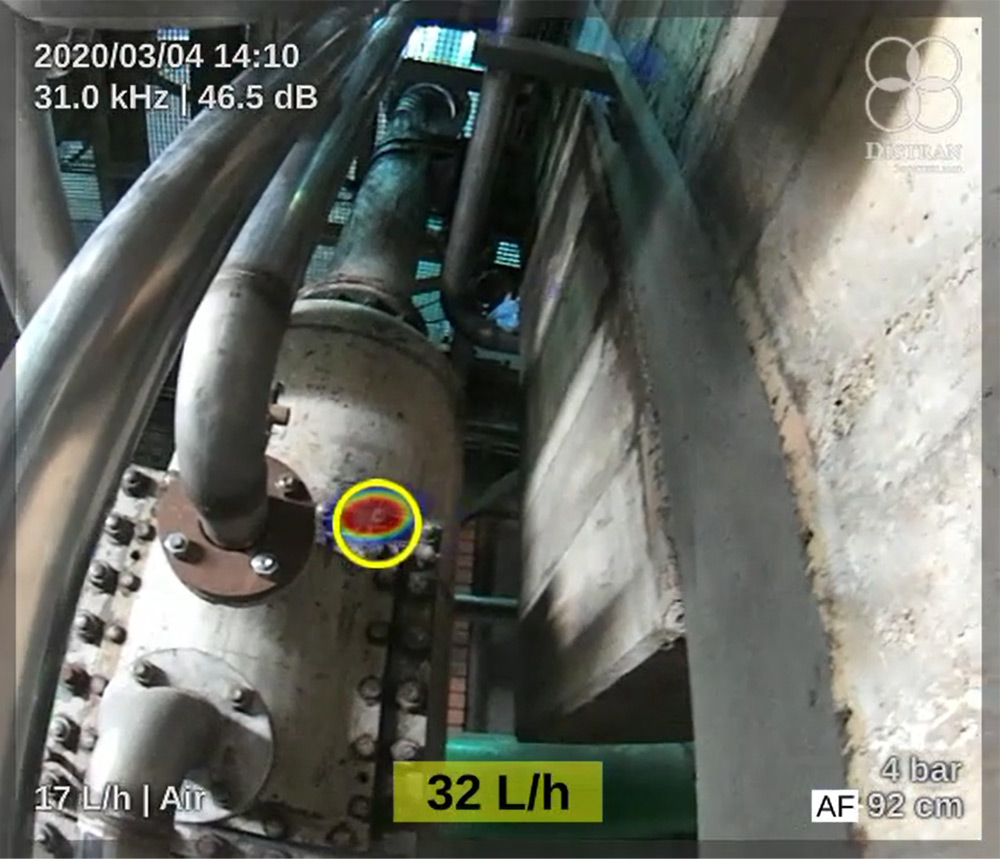

For this plant, risk comes in many chemical forms: carbon monoxide, hydrogen, nitrogen, carbon dioxide, and more. After testing the Ultra Pro X, the operations team began using it for ad hoc leak detection and regular inspections alongside existing strategies.

Now, when a gas sensor triggers an alarm, an employee uses the Distran device to verify, pinpoint, and quantify the issue from a safe distance. If the leak does not pose a risk, the operations team can approach it confidently. Once the leak is repaired, traditional methods such as soap spray can be used as targeted control instruments.

Both safety and economic considerations are essential in evaluating new technologies for risk mitigation.

Images: gas leak examples, courtesy of our clients.

Proactive leak detection with advanced technology

Images: gas leak examples, courtesy of our clients.

For this plant, risk comes in many chemical forms: carbon monoxide, hydrogen, nitrogen, carbon dioxide, and more. After testing the Ultra Pro X, the operations team began using it for ad hoc leak detection and regular inspections alongside existing strategies.

Now, when a gas sensor triggers an alarm, an employee uses the Distran device to verify, pinpoint, and quantify the issue from a safe distance. If the leak does not pose a risk, the operations team can approach it confidently. Once the leak is repaired, traditional methods such as soap spray can be used as targeted control instruments.

Both safety and economic considerations are essential in evaluating new technologies for risk mitigation.

Improving operational reliability and cost efficiency

After deploying the Ultra Pro X, the team has also discovered cost reductions and productivity gains.

“The integration and combination of Distran technology with existing methods has led to a multifold improvement in operational reliability,” said the company’s operations manager.

For example, the time and effort required for inspections has been massively reduced. Commissioning times have been reduced by a full day.

The operations manager said the Distran acoustic camera allows the company to “experience success quickly. ” Shorter inspection times, more targeted repairs, and shorter downtimes result in lower costs.

Improving operational reliability and cost efficiency

After deploying the Ultra Pro X, the team has also discovered cost reductions and productivity gains.

“The integration and combination of Distran technology with existing methods has led to a multifold improvement in operational reliability,” said the company’s operations manager.

For example, the time and effort required for inspections has been massively reduced. Commissioning times have been reduced by a full day.

The operations manager said the Distran acoustic camera allows the company to “experience success quickly. ” Shorter inspection times, more targeted repairs, and shorter downtimes result in lower costs.

“The personnel deployed

are not only better protected,

but also faster.”

Operations Manager

Enhancing maintenance with leak quantification and reporting

Leak rate quantification also makes it possible to better assess the urgency of repairs and even prevent downtime. Even small leaks in difficult-to-access areas, such as six millimetres-thin equipment lines, can be detected from afar.

Distran’s integrated reporting functionality offers new ways of documenting inspections to optimize maintenance processes further.

“Distran ultrasonic cameras do not require expert knowledge so that the user group can be flexibly expanded.

We have already equipped several sites with Distran cameras so that they can react quickly at any time. This ensures fast, safe, and reliable detection of leaks,” said the operations manager.

The Ultra Pro X is now essential to this plant’s comprehensive safety strategy.

It saves time and money without compromising safety.

Enhancing maintenance with leak quantification and reporting

Leak rate quantification also makes it possible to better assess the urgency of repairs and even prevent downtime. Even small leaks in difficult-to-access areas, such as six millimetres-thin equipment lines, can be detected from afar.

Distran’s integrated reporting functionality offers new ways of documenting inspections to optimize maintenance processes further.

“Distran ultrasonic cameras do not require expert knowledge so that the user group can be flexibly expanded.

We have already equipped several sites with Distran cameras so that they can react quickly at any time. This ensures fast, safe, and reliable detection of leaks,” said the operations manager.