24 Mar How sensitive are ultrasound cameras?

Understanding Ultrasound Cameras’ detection capabilities

How sensitive are ultrasound cameras?

Emma Lambert March 24, 2025 4 min read

Contributors: Ana Gutiérrez and Julien Rapet

The performance of ultrasound cameras in detecting gas leaks can be impacted by several external factors. Two critical variables, the detection distance, and the gas pressure, play a significant role in determining sensitivity. This variability raises several questions from which:

![]() How far can a small gas leak be detected?

How far can a small gas leak be detected?

![]() Why are some camera manufacturers claiming detection ranges up to 100 meters, while some others advertise up to 200 meters? Are those cameras able to go up to 200 meters more sensitive?

Why are some camera manufacturers claiming detection ranges up to 100 meters, while some others advertise up to 200 meters? Are those cameras able to go up to 200 meters more sensitive?

![]() Can a gas leak be detected at any pressure, or is there a minimum requirement?

Can a gas leak be detected at any pressure, or is there a minimum requirement?

Let’s answer these questions.

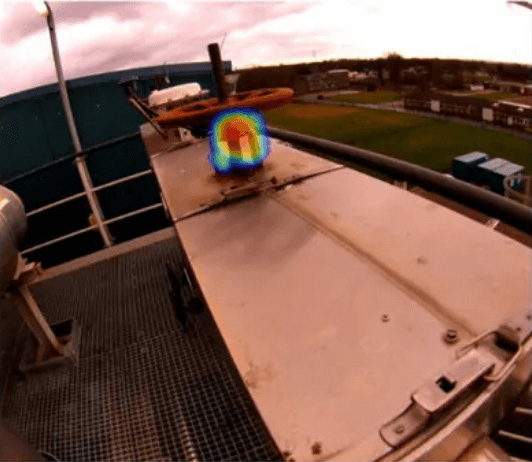

A small air leak detected on a connector by

Distran’s ultrasound camera

Understanding Ultrasound Cameras’ detection capabilities

How sensitive are ultrasound cameras?

Emma Lambert Mar 24, 2025 4 min read

Contributors: Ana Gutiérrez and Julien Rapet

The performance of ultrasound cameras in detecting gas leaks can be impacted by several external factors. Two critical variables, the detection distance, and the gas pressure, play a significant role in determining sensitivity. This variability raises several questions from which:

![]() How far can a small gas leak be detected?

How far can a small gas leak be detected?

![]() Why are some camera manufacturers claiming detection ranges up to 100 meters, while some others advertise up to 200 meters? Are those cameras able to go up to 200 meters more sensitive?

Why are some camera manufacturers claiming detection ranges up to 100 meters, while some others advertise up to 200 meters? Are those cameras able to go up to 200 meters more sensitive?

![]() Can a gas leak be detected at any pressure, or is there a minimum requirement?

Can a gas leak be detected at any pressure, or is there a minimum requirement?

Let’s answer these questions.

Ultrasound cameras are powerful and effective tools for gas leak detection, offering high performance in a wide range of conditions. Their sensitivity is defined by the smallest leak they can detect in a given setting. But, while manufacturers typically specify values of the smallest leak they can detect measured in controlled, quiet environments, at a given distance, this value can vary significantly in real-life situations due to various conditions.

Factors such as gas pressure, the distance to the leak, the background noise, and even the geometry of the leak source impact the minimum detectable leak rate. Being aware of the impact of these parameters on the ultrasound camera’s sensitivity is essential for assessing its effectiveness in specific applications.

In addition, understanding how environmental and operational conditions affect the smallest detectable leak is crucial for operators to ensure accurate and efficient gas leak inspections. These insights are especially important when safety concerns prevent operators from approaching the leak source, as they help them determine which leaks can be reliably detected under those conditions.

We have previously shown how the background noise affects the camera’s sensitivity and how one could make the camera more sensitive in noisy environments. In this article, we will explain how gas pressure and distance to the leak source affect the camera’s capabilities to detect small leaks in industrial environments. These insights will help you determine whether an ultrasound camera is the right solution for your application.

Ultrasound cameras are powerful and effective tools for gas leak detection, offering high performance in a wide range of conditions. Their sensitivity is defined by the smallest leak they can detect in a given setting. But, while manufacturers typically specify values of the smallest leak they can detect measured in controlled, quiet environments, at a given distance, this value can vary significantly in real-life situations due to various conditions.

Factors such as gas pressure, the distance to the leak, the background noise, and even the geometry of the leak source impact the minimum detectable leak rate. Being aware of the impact of these parameters on the ultrasound camera’s sensitivity is essential for assessing its effectiveness in specific applications.

In addition, understanding how environmental and operational conditions affect the smallest detectable leak is crucial for operators to ensure accurate and efficient gas leak inspections. These insights are especially important when safety concerns prevent operators from approaching the leak source, as they help them determine which leaks can be reliably detected under those conditions.

We have previously shown how the background noise affects the camera’s sensitivity and how one could make the camera more sensitive in noisy environments. In this article, we will explain how gas pressure and distance to the leak source affect the camera’s capabilities to detect small leaks in industrial environments. These insights will help you determine whether an ultrasound camera is the right solution for your application.

How does the inspection distance impact the smallest detectable leak?

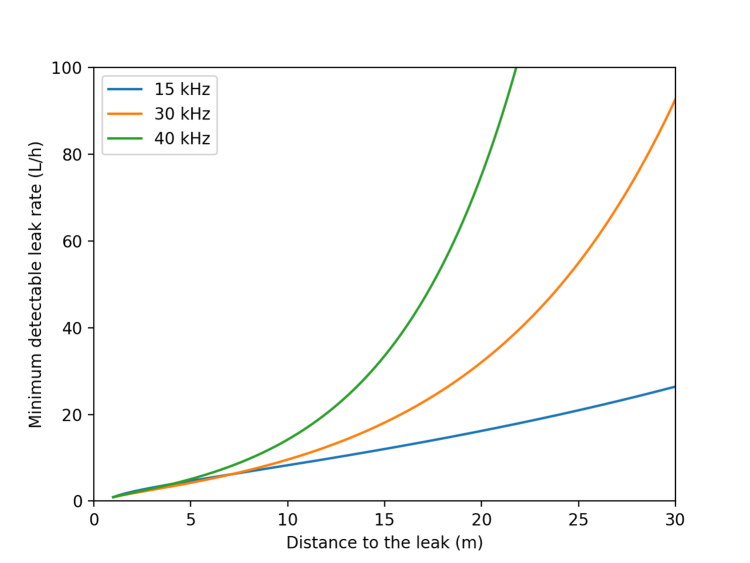

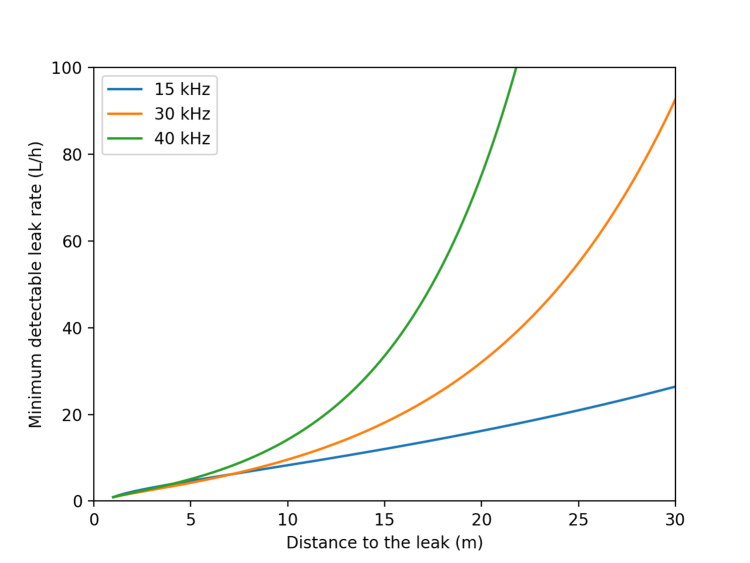

Detection distance significantly affects the camera’s ability to detect leaks because sound weakens as it travels through the air. As you move farther from the leak source, the ultrasounds emitted by the leak fade due to two main phenomena: geometric spreading, which attenuates sound intensity uniformly with distance, and air absorption, which diminishes higher-frequency ultrasound more significantly. Together, these effects make it increasingly challenging for the camera’s sensors to detect smaller leaks at greater distances.

At close distances, smaller leaks can be detected. For example, at 30 cm, Distran Ultra Pro cameras can detect gas leaks as small as 0.15 L/h.

However, as you move farther away, sound intensity attenuates, meaning that only leaks with a higher leak rate will produce enough sound for the camera to detect. This effect is particularly significant when using high detection frequencies, as these are more strongly absorbed by air and therefore propagate less over the distance. For instance, at a distance of 15 meters, the Distran ultrasound camera can detect leaks as small as 30 L/h at a detection frequency of 40 kHz. However, by lowering the detection frequency to 15 kHz, leaks as small as 10 L/h can be detected.

This highlights two key points: first, the advantage of using an ultrasound camera with adjustable detection frequencies, and second, the importance of training inspectors to achieve optimal performance under varying conditions.

For this reason, Distran offers a short, one-day training to teach users how and when adjusting the detection distance can enhance leak detection, ensuring they correctly adapt the detection frequency to avoid missing any leaks.

As a result of sound attenuation over distance, specifying a fixed maximum detection distance for ultrasound cameras is neither meaningful nor technically accurate. If the leak emits a sufficiently strong ultrasonic signal, it can be detected from hundreds of meters away. The detection distance is solely determined by the size of the detected leak. We encourage readers to refer to the figure 1 below to check the expected detectable leak sizes at the inspection distances relevant to their specific scenarios.

Figure 1: Detection threshold of a 10 bar methane pinhole leak at varying frequencies

Key takeaway:

Detecting small leaks becomes more difficult at greater distances due to sound attenuation. In such cases, adjusting the detection frequency can help – using lower frequencies, which attenuate less, can improve the chances of detecting smaller leaks.

How does the inspection distance impact the smallest detectable leak?

Detection distance significantly affects the camera’s ability to detect leaks because sound weakens as it travels through the air. As you move farther from the leak source, the ultrasounds emitted by the leak fade due to two main phenomena: geometric spreading, which attenuates sound intensity uniformly with distance, and air absorption, which diminishes higher-frequency ultrasound more significantly. Together, these effects make it increasingly challenging for the camera’s sensors to detect smaller leaks at greater distances.

At close distances, smaller leaks can be detected. For example, at 30 cm, Distran Ultra Pro cameras can detect gas leaks as small as 0.15 L/h.

However, as you move farther away, sound intensity attenuates, meaning that only leaks with a higher leak rate will produce enough sound for the camera to detect. This effect is particularly significant when using high detection frequencies, as these are more strongly absorbed by air and therefore propagate less over the distance. For instance, at a distance of 15 meters, the Distran ultrasound camera can detect leaks as small as 30 L/h at a detection frequency of 40 kHz. However, by lowering the detection frequency to 15 kHz, leaks as small as 10 L/h can be detected.

This highlights two key points: first, the advantage of using an ultrasound camera with adjustable detection frequencies, and second, the importance of training inspectors to achieve optimal performance under varying conditions.

For this reason, Distran offers a short, one-day training to teach users how and when adjusting the detection distance can enhance leak detection, ensuring they correctly adapt the detection frequency to avoid missing any leaks.

As a result of sound attenuation over distance, specifying a fixed maximum detection distance for ultrasound cameras is neither meaningful nor technically accurate. If the leak emits a sufficiently strong ultrasonic signal, it can be detected from hundreds of meters away. The detection distance is solely determined by the size of the detected leak. We encourage readers to refer to the figure 1 below to check the expected detectable leak sizes at the inspection distances relevant to their specific scenarios.

Figure 1: Detection threshold of a 10 bar methane pinhole leak at varying frequencies

Key takeaway:

Detecting small leaks becomes more difficult at greater distances due to sound attenuation. In such cases, adjusting the detection frequency can help – using lower frequencies, which attenuate less, can improve the chances of detecting smaller leaks.

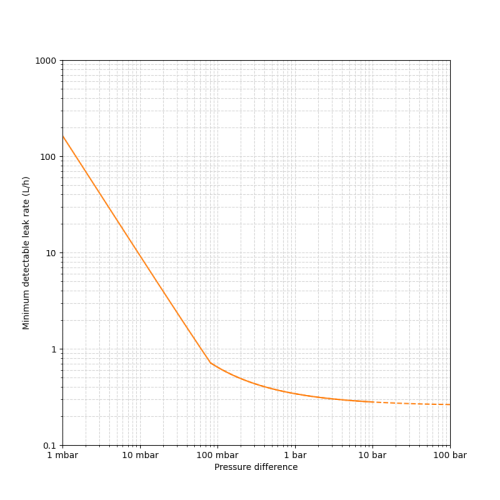

How does the gas pressure affect ultrasound cameras’ sensitivity?

When gas leaks occur, the escaping gas causes vibrations in the air due to the pressure difference between the system and the surrounding environment. These vibrations generate ultrasound waves, and for larger leaks, they can also produce audible sounds. Therefore, a pressure difference is required for gas leaks to be detected with an ultrasound camera. This explains why ultrasound cameras cannot detect gas clouds, for example. However, establishing a minimum pressure difference for detection is not straightforward, as there is a strong dependence between the pressure difference and the size of the detectable leak.

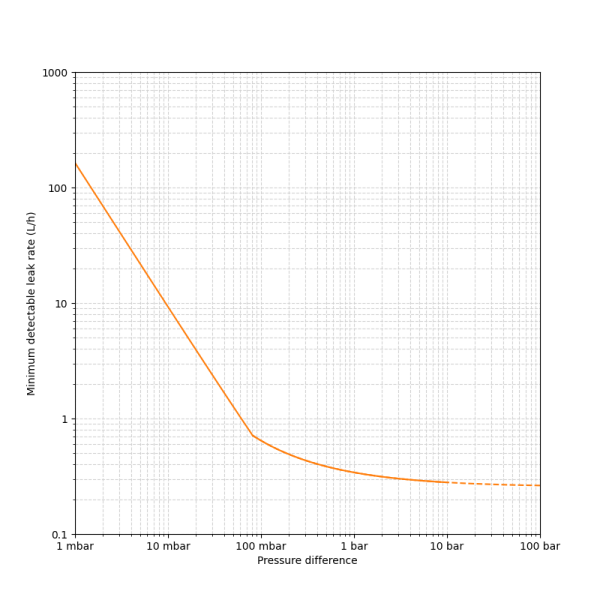

As shown in Figure 2, when the pressure difference is low—especially below 1 bar, as can occur in ventilation ducts or gas delivery systems in residential and commercial buildings—only larger leaks generate enough ultrasounds to be detected. The lower the pressure difference, the larger the leak must be to produce a detectable ultrasound signal.

For example, in a system with a pressure difference of only 1 mbar, the detection threshold is approximately 200 L/h. If the pressure difference increases slightly to 10 mbar, the threshold improves significantly to around 10 L/h. This highlights the strong relationship between pressure difference and the minimum detectable leak size in this pressure regime.

In contrast, in systems operating under higher pressures, the gas molecules are moving faster because the higher pressure allows them to reach greater velocities.

This results in more turbulent gas flow, which generates stronger ultrasonic noise and thus allows for the identification of smaller leaks.

For example, at pressures above 1 bar, leaks greater than 0.5 L/h can be detected. In this regime, beyond approximately 1 to 10 bar, the smallest detectable leak rate reaches a plateau and further increases in pressure are not expected to impact the detection threshold as it can be seen in Figure 2.

Figure 2: Detection threshold of a methane pinhole leak at 1 m at 30 kHz

Key takeaway:

Higher gas pressure enhances leak detection by generating stronger ultrasonic noise, making it easier to identify smaller leaks. In low-pressure systems, only larger leaks produce detectable ultrasound. Ultimately, the effectiveness of an ultrasound camera for low-pressure systems depends on the target leak size you aim to detect.

How does the gas pressure affect ultrasound cameras’ sensitivity?

When gas leaks occur, the escaping gas causes vibrations in the air due to the pressure difference between the system and the surrounding environment. These vibrations generate ultrasound waves, and for larger leaks, they can also produce audible sounds. Therefore, a pressure difference is required for gas leaks to be detected with an ultrasound camera. This explains why ultrasound cameras cannot detect gas clouds, for example. However, establishing a minimum pressure difference for detection is not straightforward, as there is a strong dependence between the pressure difference and the size of the detectable leak.

As shown in Figure 2, when the pressure difference is low—especially below 1 bar, as can occur in ventilation ducts or gas delivery systems in residential and commercial buildings—only larger leaks generate enough ultrasounds to be detected. The lower the pressure difference, the larger the leak must be to produce a detectable ultrasound signal.

For example, in a system with a pressure difference of only 1 mbar, the detection threshold is approximately 200 L/h. If the pressure difference increases slightly to 10 mbar, the threshold improves significantly to around 10 L/h. This highlights the strong relationship between pressure difference and the minimum detectable leak size in this pressure regime.

In contrast, in systems operating under higher pressures, the gas molecules are moving faster because the higher pressure allows them to reach greater velocities. This results in more turbulent gas flow, which generates stronger ultrasonic noise and thus allows for the identification of smaller leaks. For example, at pressures above 1 bar, leaks greater than 0.5 L/h can be detected. In this regime, beyond approximately 1 to 10 bar, the smallest detectable leak rate reaches a plateau and further increases in pressure are not expected to impact the detection threshold as it can be seen in Figure 2.

Figure 2: Detection threshold of a methane pinhole leak at 1 m at 30 kHz

Key takeaway:

Higher gas pressure enhances leak detection by generating stronger ultrasonic noise, making it easier to identify smaller leaks. In low-pressure systems, only larger leaks produce detectable ultrasound. Ultimately, the effectiveness of an ultrasound camera for low-pressure systems depends on the target leak size you aim to detect.

Emma Lambert

Emma Lambert is a Technical Content Specialist at Distran with over two years of experience bridging the gap between marketing and applications engineering teams. She creates high-impact content that translates complex technical concepts into clear, engaging materials—helping industrial professionals understand and adopt cutting-edge ultrasound technology for gas leak detection.

Emma Lambert

Emma Lambert is a Technical Content Specialist at Distran with over two years of experience bridging the gap between marketing and applications engineering teams. She creates high-impact content that translates complex technical concepts into clear, engaging materials—helping industrial professionals understand and adopt cutting-edge ultrasound technology for gas leak detection.