24 Jul TotalEnergies: Safer turnarounds and more efficient restarts

TotalEnergies: safer turnarounds and more efficient restarts

Meeting TotalEnergies’ “Zero Tolerance” for leaks

A turnaround on TotalEnergies platforms is a significant moment, from its preparatory phase to the resumption of operations. It answers different purposes:

![]() To reduce risks by modernizing and upgrading facilities

To reduce risks by modernizing and upgrading facilities

![]() To reinforce safety and regulatory compliance

To reinforce safety and regulatory compliance

![]() For preventive maintenance to avoid failures

For preventive maintenance to avoid failures

![]() To protect the environment from harmful emissions

To protect the environment from harmful emissions

TotalEnergies: safer turnarounds and more efficient restarts

Meeting TotalEnergies’ “Zero Tolerance” for leaks

A turnaround on TotalEnergies platforms is a significant moment, from its preparatory phase to the resumption of operations. It answers different purposes:

![]() To reduce risks by modernizing and upgrading facilities

To reduce risks by modernizing and upgrading facilities

![]() To reinforce safety and regulatory compliance

To reinforce safety and regulatory compliance

![]() For preventive maintenance to avoid failures

For preventive maintenance to avoid failures

![]() To protect the environment from harmful emissions

To protect the environment from harmful emissions

This article describes how the TotalEnergies team deploys Ultra Pro X to ensure safe, quick, and comprehensive leak detection during shutdowns and daily operations:

1. TotalEnergies Feyzin platform: a critical industrial hub

2. The huge scope of containment

3. Planned shutdowns on tight schedules

4. Bursting the bubble: the reality of using soap spray

5. Looking through the Ultra Pro X

6. Immediate impact on shutdowns

7. Bonus benefits for maintenance and emergencies

8. TotalEnergies Feyzin platform: gas leak detection in a nutshell

A critical industrial hub

The TotalEnergies Feyzin complex, south of Lyon, is a pillar of the French oil industry. Its refining and petrochemical processing activities support one of the most dynamic markets in France and unfold across a vast territory:

- Crude oil and petroleum storage in Saint-Quentin-Fallavier and Serpaize

- Ethylene storage in Viriat

- Over 1,200 kilometers of pipelines, notably along the Lavéra-Karlsruhe axis

These facilities process 5 million tons of crude oil annually, employing 600 people among which half work shifts, 24 hours a day, 7 days a week. TotalEnergies aims to attain the highest safety standards and deliver innovative solutions for a sustainable future while meeting national energy demands.

Gas leak detection is a top priority for operating safely and efficiently at a high-threshold Seveso site in this peri-urban environment. Stringent safety measures are applied to mitigate risks to personnel and residents. Indeed, more than 150 million euros were invested in the last 10 years to improve its environmental impact.

The operations team proactively searches for leaks during daily rounds and in preparation for the resumption of operations after a shutdown.

The huge scope of containment

Maintenance and upgrades on the industrial equipment at Feyzin require special logistics. Hundreds of flanges, sensors, and other pieces of equipment are dismantled and overhauled. A shutdown usually lasts 5 weeks and involves up to 100 people, some of whom are specially trained in jointing.

Upon completion of the core activities, quality assurance inspections ensure a smooth resumption of production. All containers, pipes, valves, and equipment must be secure and leak-free to prevent any unintended release of these substances into the environment or surrounding areas. It’s a critical aspect of safety and environmental protection in industrial operations. No loss of containment is acceptable upon restart.

Even components untouched during the shutdown must be checked as efficiently as possible. Traditionally, this is a long and demanding process involving dozens of people over several days. They must inspect complex, hard-to-reach installations and individually assess thousands of flanges. ~1,300 flanges inthe Alkylation unit alone.

Planned shutdowns on tight schedules

During a shutdown, time is of the essence. With traditional methods, a large number of people are mobilized simultaneously for this task, in order to bring the installations back to production within the allotted time. Complex and hard-to-reach installations further complicate operations, while any delay is costly.

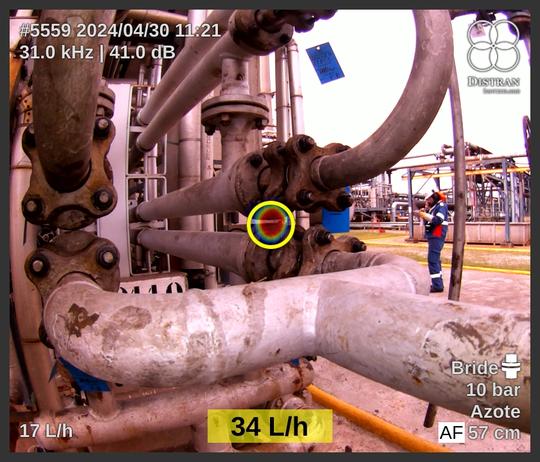

This is why solutions such as Distran cameras, which detect inert gases such as nitrogen, are essential. The Distran camera indicates leak points immediately, clearly, and remotely, allowing maintenance operations to be carried out quickly while ensuring the systems’ tightness.

“Inspections are carried out remotely, easily, quickly, and, above all, safely.

The Ultra Pro X has become an indispensable tool.

It is constantly in use in the various units.”

Vincent Leleux

Deputy Head of Operations, TotalEnergies Feyzin

Bursting the bubble: the reality of using soap spray

The traditional method used to check flanges was time-consuming, tedious, and labor-intensive. It involved taping all flanges, piercing the strips, applying soapy water, and checking for bubbles.

For flanges that were difficult to access, high off the ground, or with large diameters, the inspectors had to install scaffolding.

If bubbles appear, a leak is present. However, the severity and nature of the leak are still unknown without further equipment and analysis.

Bursting the bubble: the reality of using soap spray

The traditional method used to check flanges was time-consuming, tedious, and labor-intensive. It involved taping all flanges, piercing the strips, applying soapy water, and checking for bubbles.

For flanges that were difficult to access, high off the ground, or with large diameters, the inspectors had to install scaffolding.

If bubbles appear, a leak is present. However, the severity and nature of the leak are still unknown without further equipment and analysis.

Looking through the Ultra Pro X

The team at TotalEnergies Feyzin deployed Distran’s acoustic camera, the Ultra Pro X. Their intention was to maximize efficiency during the phase of a shutdown.

Using its ultrasonic microphones, the Ultra Pro triangulates the precise source of ultrasounds emitted by a leak. It can even also detect leaks in highly complex piping installations. Operators can pinpoint a leak in any direction, up, down, left or right: the camera offers a 180-degree detection angle. Plus, if a leak is detected beyond the field of view of the display, an indicator on the edge of the screen prompts the operator to turn the device. In real-time, the operator sees the location of a defect, and its leak rate in liters per hour.

On large and complex units, the operator remains on the ground, pinpoints a leak from a distance, zooms in on the display, and takes a closer look without moving closer to the equipment. Operators find the camera to be lightweight, portable and easy to use in confined spaces, even one-handed to always keep one hand on the handrail whenever necessary.

Same gas leak, two different views:

C4 (Butane) leak between two flanges viewed from two sides

This leak of C4 occurred between two flanges, spaced just 2 centimeters apart. Once located, operators realized they could see a short plume from a certain angle and in certain light and background conditions. Due to the angle (lower than height of eyes), unveiling this leak would have been challenging and time-consuming. However, with the precision of the Ultra Pro X, pinpointing the leak location from any side and in standard weather conditions was effortless.

Immediate impact on shutdowns

Gas leak indication at a distance

Alkilation unit leak indication at a distance

Right from the start, Feyzin’s team used the Ultra Pro X to pinpoint gas leaks instantly, no matter how complex the installation. Faulty seals, for example, were located remotely, quickly and easily. This has had the positive effect of improving the responsiveness of maintenance operations.

Compared to soap spray, the Ultra Pro has considerably accelerated the team’s leak detection processes and enables them to meet tight shutdown schedules with less effort and resources.

“The other fundamental aspect of the camera is its long range.

Indeed, teams can locate leaks from 30-40 meters away, without wasting time, and without needing a lift or scaffolding and all the associated transport, assembly, and safety constraints.”, says Vincent Leleux, Deputy Head of Operations of TotalEnergies Feyzin.

Any delay in the resumption of operations is costly.

If a unit fails to return to production on time, the facility may be forced to overstock or reroute raw materials. The delayed production can result in transportation and routing complications as river transport services to the Feyzin site are particularly challenging.

But before resuming operations, the team must carefully inspect the equipment. TotalEnergies is committed to maintaining total control over its systems, with a “zero leaks” requirement before any unit is restarted.

Now the inspection team can guarantee a faster return to service, while keeping in line with TotalEnergies’ “zero tolerance” criteria.

How Distran Ultra Pro ultrasound cameras support refineries:

SAFETY

The use of Ultra Pro X helps to limit operations that could create risky situations for operators during inspections:

- Reduced reliance on scaffolding and lifts

- No contact with gases required for detection

- ATEX, IECEx, and UL HazLoc certified equipment

RELIABILITY

Detection of all types of gases present on the site is achieved with a single tool.

The device helps avoiding units’ shutdown by providing clear and immediate leak indication, pinpointing and rate quantification.

AVAILABILITY

Control rooms are equipped with Distran cameras, available to teams 24/7.

~300 personnel use Ultra Pro X due to the device’s ease of use and high reliability on the field.

SPEED & RESPONSE TIME

Drastic reduction in man-hours during a unit. Teams do not need to scan each element; the Distran camera detects and precisely locates leaks within a 180° field in front of it.

The device is deployed in seconds and is immediately operational to detect and locate potential leaks.

Bonus benefits for maintenance and emergencies

Beyond accelerating their existing processes, the Feyzin team found more applications for Distran cameras.

Another option for testing equipment before going online involves pressurizing systems with nitrogen. However, not all detection tools are sensitive to nitrogen.

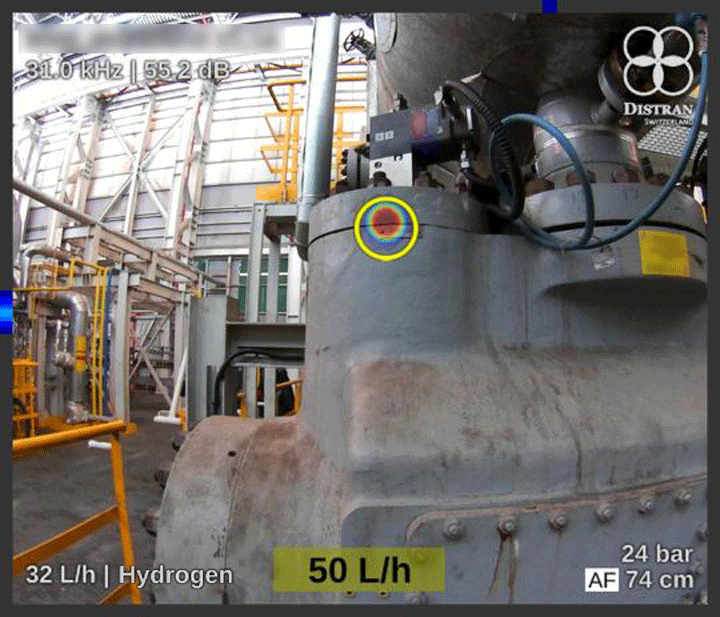

Hydrogen is also tricky, as it’s light and odorless. Small hydrogen leaks are especially difficult to detect.

Because the Distran device detects leaks of any gas, TotalEnergies decided to incorporate it into the daily process of proactive leak detection and analysis. With the Ultra Pro’s 180° field of detection, inspectors can ensure they are covering more ground, rapidly validating that no leaks are present. They know that if a leak occurs in an unsuspecting location, the Distran device will pick it up. Its versatility enables it to handle all the gases present on the platform: hydrocarbons, hydrogen, nitrogen, compressed air, vacuum, steam, and more.

The cameras have become the team’s primary tool for maintenance rounds, pinpointing leaks of any type of gas. They are now widely integrated into the site’s day-to-day operations, helping to maintain safety and reliability standards.

The Ultra Pro X cameras are also deployed for incidental events. Initially, these ultrasonic cameras were reserved for a small team of experts. Due to their ease of use, TotalEnergies expanded the deployment. Some 300 operators have been trained on how to grab an Ultra Pro in an emergency.

Hydogren leak examples, courtesy of our clients

Bonus benefits for maintenance and emergencies

Beyond accelerating their existing processes, the Feyzin team found more applications for Ultra Pro X cameras.

Another option for testing equipment before going online involves pressurizing systems with nitrogen. However, not all detection tools are sensitive to nitrogen.

Hydrogen is also tricky, as it’s light and odorless. Small hydrogen leaks are especially difficult to detect.

Because the Distran device detects leaks of any gas, TotalEnergies decided to incorporate it into the daily process of proactive leak detection and analysis. With the Ultra Pro’s 180° field of detection, inspectors can ensure they are covering more ground, rapidly validating that no leaks are present. They know that if a leak occurs in an unsuspecting location, the Distran device will pick it up. Its versatility enables it to handle all the gases present on the platform: hydrocarbons, hydrogen, nitrogen, compressed air, vacuum, steam, and more.

The cameras have become the team’s primary tool for maintenance rounds, pinpointing leaks of any type of gas. They are now widely integrated into the site’s day-to-day operations, helping to maintain safety and reliability standards.

The Ultra Pro X cameras are also deployed for incidental events. Initially, these ultrasonic cameras were reserved for a small team of experts. Due to their ease of use, TotalEnergies expanded the deployment. Some 300 operators have been trained on how to grab an Ultra Pro in an emergency.

“Beyond shutdowns, some gases like hydrogen, which are light and odorless,

are difficult to detect, especially with small leaks.

With Distran, operators’ work is faster and safer, ensuring optimal safety.”

Vincent Leleux

Deputy Head of Operations, TotalEnergies Feyzin

Distran’s Ultra Pro X enables safe, quick, and comprehensive leak detection during shutdowns and daily operations

- Strict timelines and a zero-leak policy are upheld during planned shutdowns,

- Maintenance teams work efficiently, inspecting large complex units from the ground,

- Hydrogen, nitrogen and other gases are detected with one versatile device,

- Operators no longer need to come in contact with a gas to detect and quantify a leak,

- 300 employees have been trained to operate the cameras, available 24 hours a day in control rooms across the Feyzin Platform.