Keep your plant safe and running with sonic precision

SonicView is an acoustic gas leak detection system that covers large volumes with pinpoint accuracy.

Unlike traditional detectors, which wait for the gas clouds to reach the sensor, SonicView detects leaks instantly using Acoustic Leak Imaging technology (ALI).

With zone-specific alerts and seamless integration into existing systems, it delivers the reliability that plant operations demand while minimizing false alarms that shut down plants unnecessarily.

From unmanned sites to complex industrial facilities, SonicView delivers 24/7 gas leak monitoring with intuitive visual confirmation of leaks of any gas type, including invisible and flammable gases like hydrogen, across vast areas.

Cover more ground. Respond faster.

Acoustic Gas Leak Detection System: DETECT LEAKS EARLY, ACT FAST, STAY SAFE

Keep your plant safe and running with sonic precision

SonicView is an acoustic gas leak detection system that covers large volumes with pinpoint accuracy.

Unlike traditional detectors, which wait for the gas clouds to reach the sensor, SonicView detects leaks instantly using Acoustic Leak Imaging technology (ALI).

With zone-specific alerts and seamless integration into existing systems, it delivers the reliability that plant operations demand while minimizing false alarms that shut down plants unnecessarily.

From unmanned sites to complex industrial facilities, SonicView delivers 24/7 gas leak monitoring with intuitive visual confirmation of leaks of any gas type, including invisible and flammable gases like hydrogen, across vast areas.

Cover more ground. Respond faster.

Coverage

20m detection radius

180° field of view

Instant leak detection

Get leak location

within seconds

Leak rate from

0,075 g/s at 20 m

(for hydrogen 1 bar)

High selectivity

Low false alerts

Live view &

rewind footage

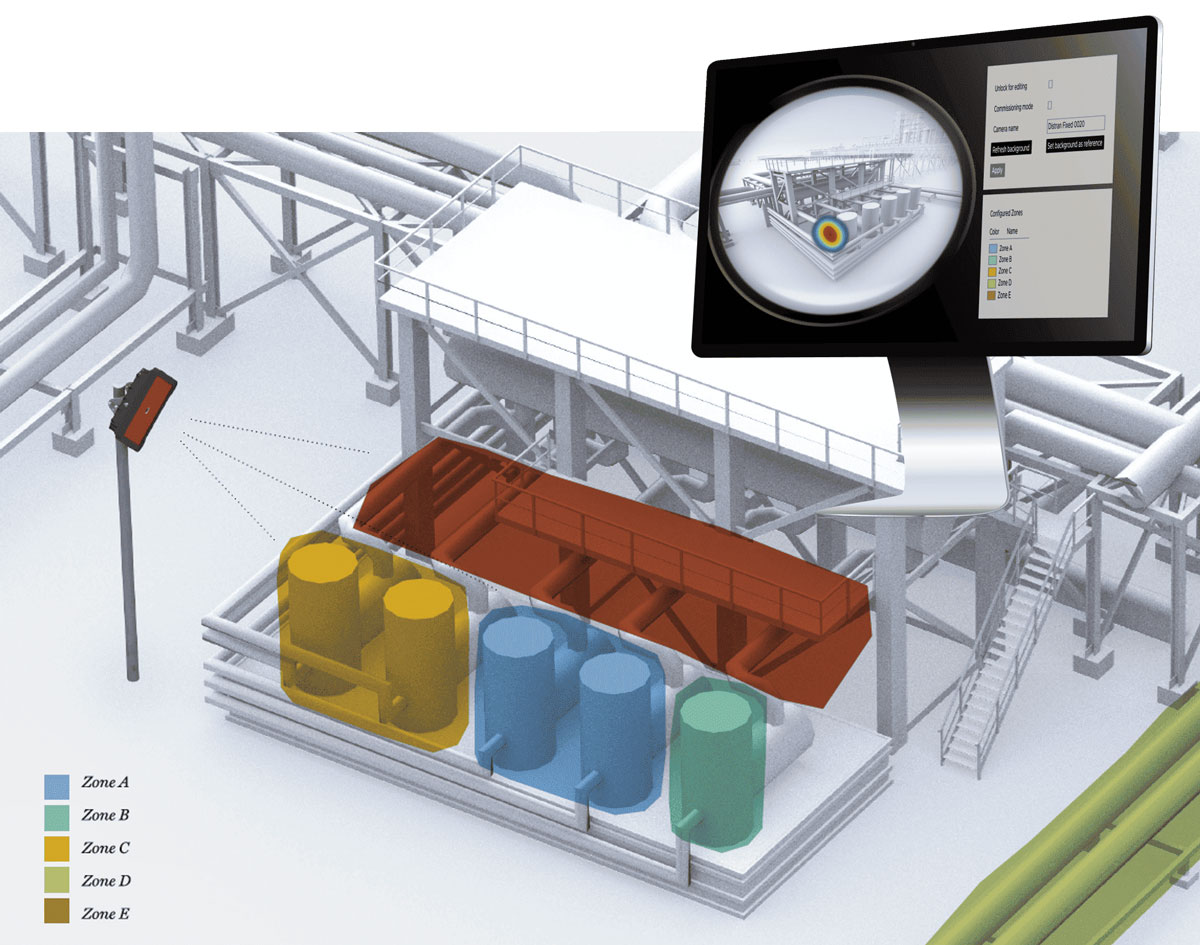

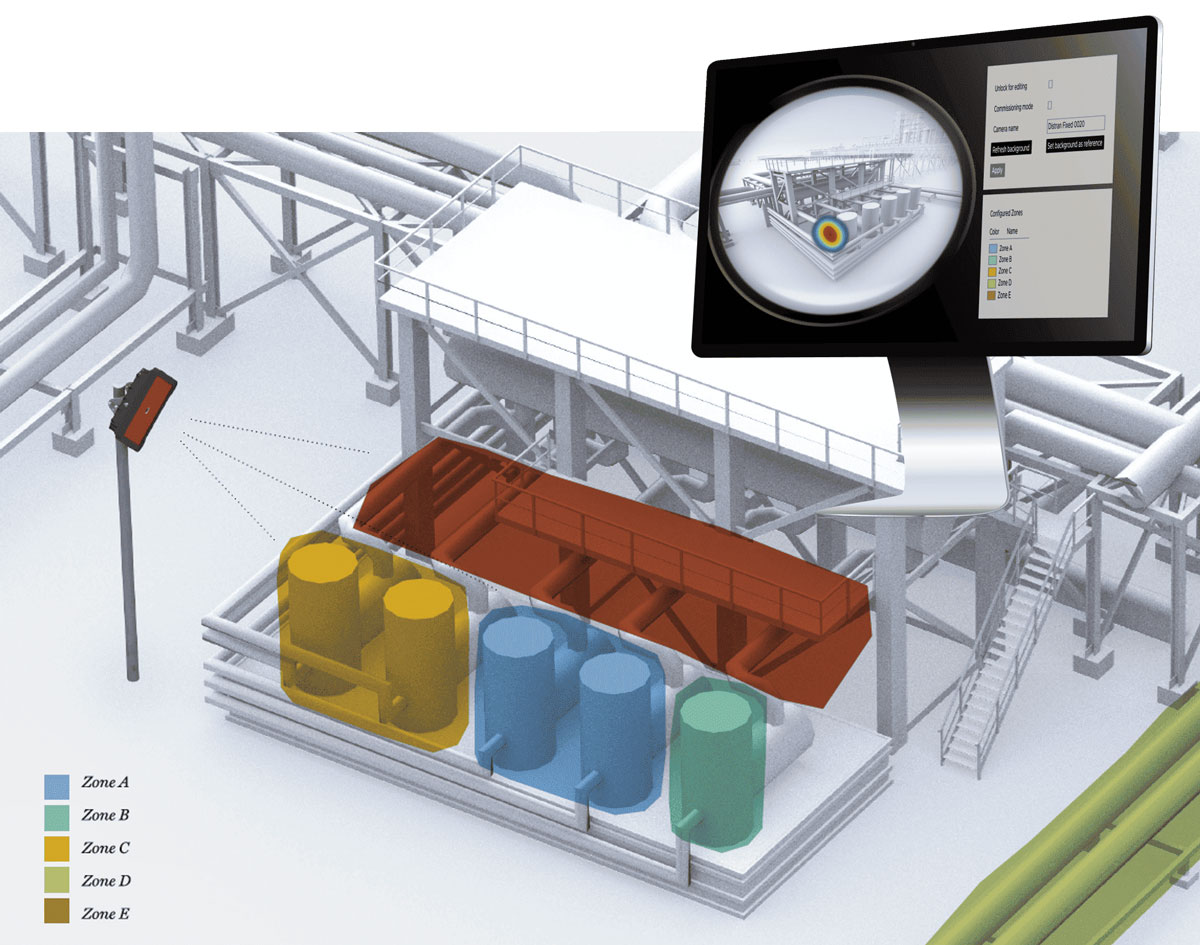

AVOID FALSE ALERTS: SELECT CRITICAL AREAS TO MONITOR, IGNORE OTHERS

Cover a wide area, react specifically

Set up zones to monitor, leak thresholds, and visualize leaks live from the web interface.

Distran SonicView’s acoustic gas leak detection system captures gas leak ultrasounds across a 20-meter radius and a 180° angle, even outdoors and in windy conditions.

The system triggers specific actions depending on the leak’s location and severity, from mailing the maintenance team for a nitrogen leak to shutting down the installation for major hydrogen leaks.

- Lower infrastructure costs: a single detector covers a 20-meter radius area

- Zone-specific response: configure different actions depending on the location and severity of the leak.

- No shutting down of your plant’s operations for non-critical leaks.

- 2 concept levels of alerts: low for maintenance, high for safety.

Set up zones to monitor, leak thresholds, and visualize leaks live from the web interface.

AVOID FALSE ALERTS: SELECT CRITICAL AREAS TO MONITOR, IGNORE OTHERS

Cover a wide area, react specifically

Distran SonicView’s acoustic gas leak detection system captures gas leak ultrasounds across a 20-meter radius and a 180° angle, even outdoors and in windy conditions.

The system triggers specific actions depending on the leak’s location and severity, from mailing the maintenance team for a nitrogen leak to shutting down the installation for major hydrogen leaks.

- Lower infrastructure costs: a single detector covers a 20-meter radius area

- Zone-specific response: configure different actions depending on the location and severity of the leak.

- No shutting down of your plant’s operations for non-critical leaks.

- 2 concept levels of alerts: low for maintenance, high for safety.

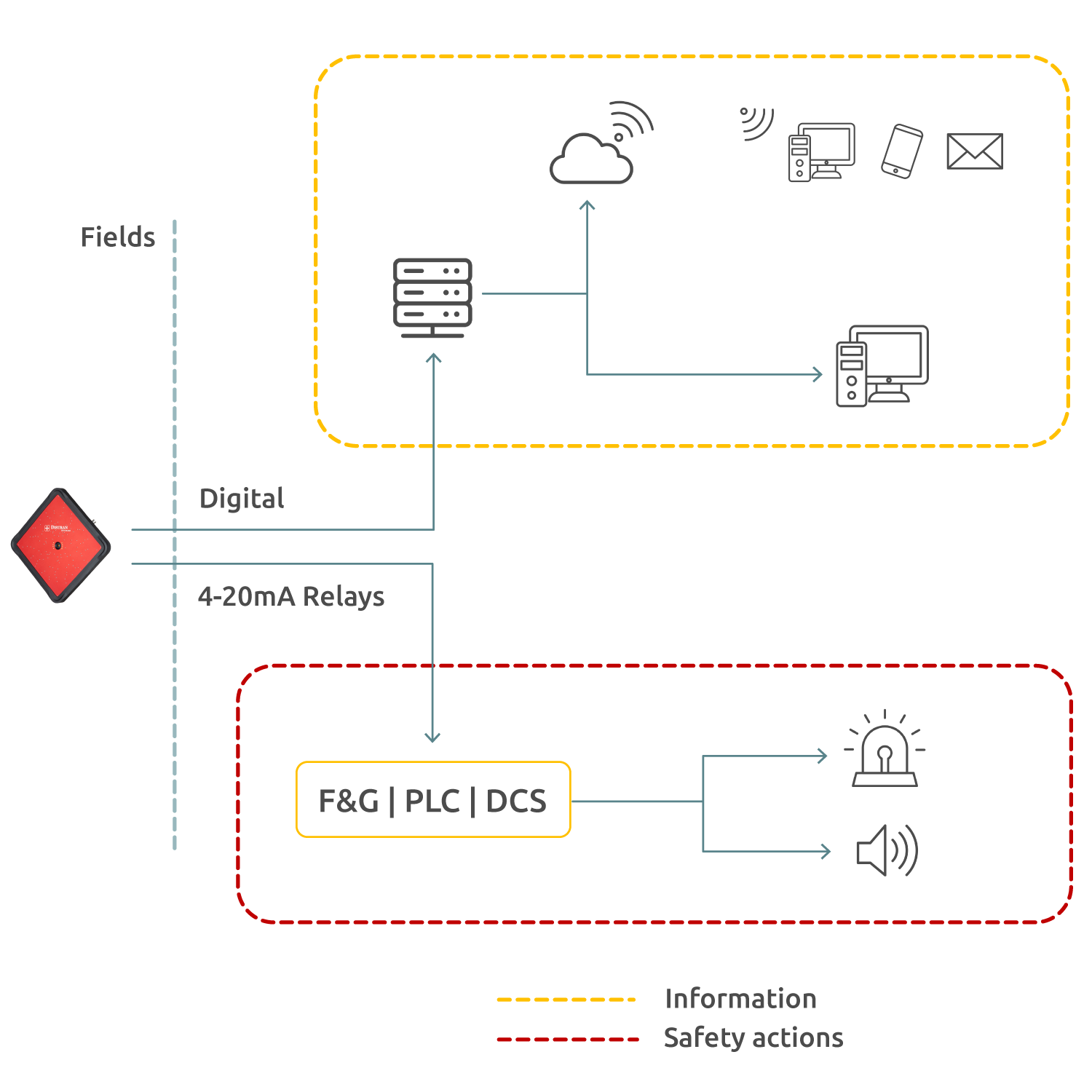

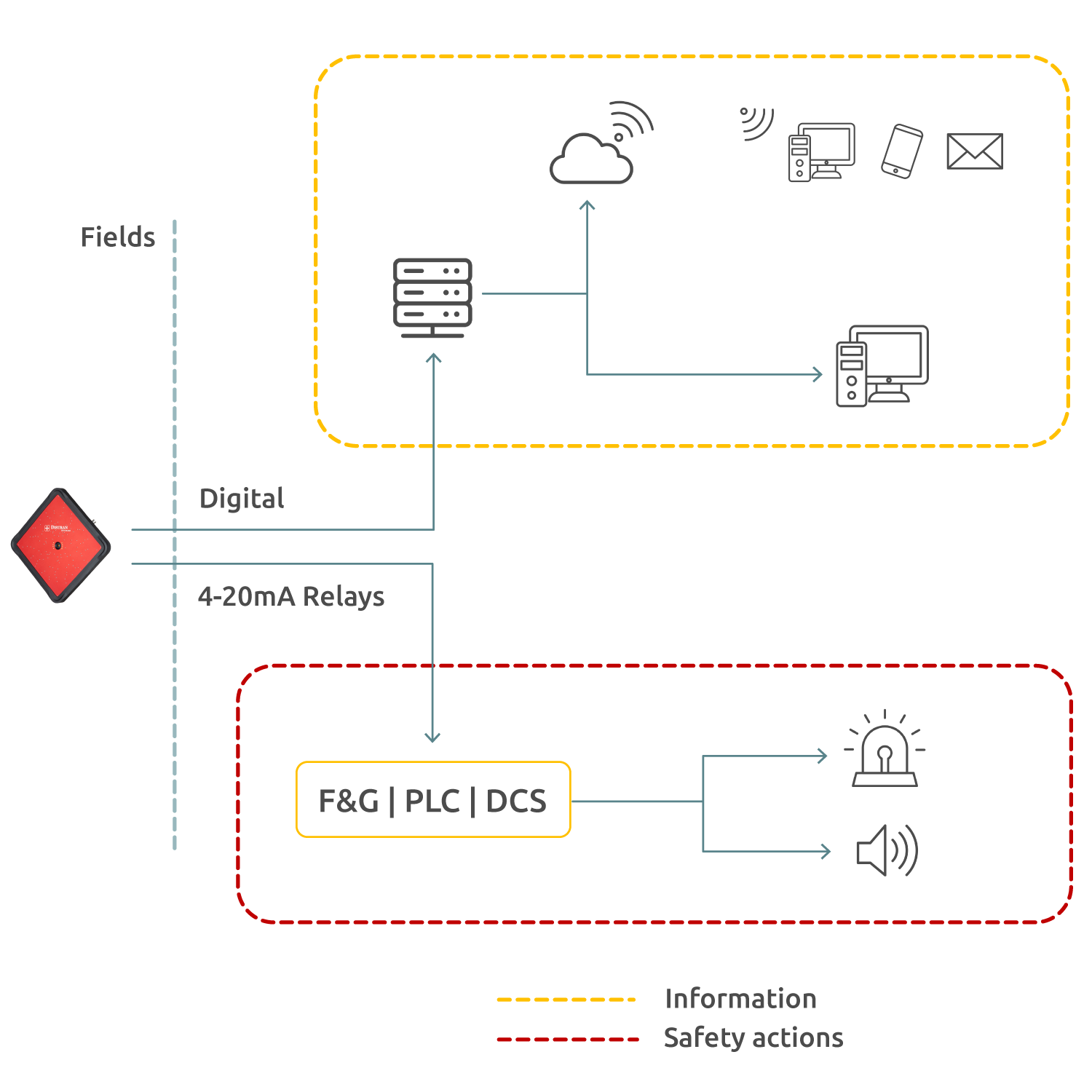

FLEXIBLE ALERT DELIVERY

Alerts your way: every channel, every team

SonicView integrates seamlessly with your existing infrastructure through multiple output options, from traditional dry contacts to modern SMS notifications.

This flexibility ensures alerts reach the right people through the channels they already use, whether:

- triggering existing alarm systems (such as your existing Fire and Gas system, PLC, DCS, through relays, 4-20mA or OPC-UA),

- sending direct messages to maintenance teams,

- or integrating with your facility’s control room protocols (e.g Web/TCP, RTSP).

FLEXIBLE ALERT DELIVERY

Alerts your way: every channel, every team

SonicView integrates seamlessly with your existing infrastructure through multiple output options, from traditional dry contacts to modern SMS notifications.

This flexibility ensures alerts reach the right people through the channels they already use, whether:

- triggering existing alarm systems (such as your existing Fire and Gas system, PLC, DCS, through relays, 4-20mA or OPC-UA),

- sending direct messages to maintenance teams,

- or integrating with your facility’s control room protocols (e.g Web/TCP, RTSP).

BUILT TO SURVEY. PROVEN ON THE FIELD.

See it, solve it: remote assessment and root cause analysis with ALI

Leak captured at the TADI test site in Lacq, France – a cutting-edge industrial simulation facility.

This example shows SonicView instantly detecting and visualizing a controlled methane leak of just 0.5 g/s, demonstrating its precision in realistic plant conditions.

LIVE & REMOTE VISUAL VERIFICATION:

When an alert triggers, operators can remotely access SonicView’s visual interface to see the exact location and characteristics of the detected leak.

This remote diagnostic capability allows you to assess the severity and determine whether immediate on-site intervention is required or if the situation can be managed through other means, reducing unnecessary emergency responses.

THOROUGH ROOT-CAUSE ANALYSIS:

After a leak happens, SonicView lets you rewind time and replay events to see exactly what occurred when the leak started.

This helps you plan corrective actions while the leaky system is offline.

SonicView detects, locate, contain, and resolve leaks quickly.

BUILT TO SURVEY. PROVEN ON THE FIELD.

See it, solve it: remote assessment and root cause analysis with ALI

Leak captured at the TADI test site in Lacq, France – a cutting-edge industrial simulation facility.

This example shows SonicView instantly detecting and visualizing a controlled methane leak of just 0.5 g/s, demonstrating its precision in realistic plant conditions.

LIVE & REMOTE VISUAL VERIFICATION:

When an alert triggers, operators can remotely access SonicView’s visual interface to see the exact location and characteristics of the detected leak.

This remote diagnostic capability allows you to assess the severity and determine whether immediate on-site intervention is required or if the situation can be managed through other means, reducing unnecessary emergency responses.

THOROUGH ROOT-CAUSE ANALYSIS:

After a leak happens, SonicView lets you rewind time and replay events to see exactly what occurred when the leak started.

This helps you plan corrective actions while the leaky system is offline.

SonicView detects, locate, contain, and resolve leaks quickly.

WE SUPPORT YOU FROM TESTING TO IMPLEMENTATION TO COMMISSIONING

Services we provide alongside SonicView

PROJECT MANAGEMENT

Benefit from manufacturer’s expertise from initial planning to system commissioning through our project management team.

SITE SURVEY & PLACEMENT OPTIMIZATION

We advise you to ensure detectors are installed in the most effective positions/locations, tailored to your plant’s specific layout and risk zones, to maximize coverage and minimize the risk of missed leaks.

TAILORED COMMISSIONING

LED BY SPECIALISTS

Our experts configure the system according to your exact requirements, ensuring that all alarm thresholds, zones, and integrations meet your operational and safety goals from the start.

ROLE-BASED TRAINING

& RESPONSE PREPAREDNESS

We provide role-specific training for operators, safety teams, and supervisors, ensuring each team member can accurately interpret alerts and execute proper response protocols for different leak scenarios.

Improve your facility’s safety and minimize false alarms that shut down plants unnecessarily with SonicView.

Technical specifications

| Detected gases | All compressed gases incl. air, vacuum and steam |

| Range | 50 L/min (0,075 g/s) at 20 meters (hydrogen 1 bar) | 1.8 scf/min (0.01 lb/min) at 70 feet (hydrogen 14,5 psi) Typical (dependent on background noise and alert threshold) |

| Cone of detection | 180° |

| Response time | 1 second |

| Relays | 2x relays. Fault and Alarm Max. 30 V AC/DC, max. 1A resistive load |

| Analog Output Signal | 4-20 mA sink or source |

| Digital communications | Industrial data communication protocol to PLCs (alarm data): OPC-UA Server over Ethernet Live video-stream: RTSP Configuration and commissioning, live view and alert log and replay: password-protected web Interface accessible from local network |

| Event logs | Data of last 10'000 alerts and start photos of last 100 alerts stored on internal memory |

| Weather protection | IP65 |

| Safety Approvals | ATEX/IECEx ( Approval pending) II 3G Ex ec ic IIC T4 Gc II 3D Ex ec ic IIIC T135°C Dc Tamb = -20°C to 50°C |

| Dimensions and Weight | Device: 272 x 272 x 50 mm, 1.5 kg | 10.71 x 10.71 x 1.97 in, 3.4 lb Device and mounting bracket: 272 x 272 x 155 mm, 1.9 kg | 10.71 x 10.71 x 6.10 in, 4.2 lb Device, mounting bracket and U-bolt plate: 272 x 272 x 160 mm, 2.6 kg | 10.71 x 10.71 x 6.30 in, 5.8 lb |

| Calibration | Calibrated at factory, field calibration not required |

–

Frequently Asked Questions

What is the difference between the portable and the fixed Distran solutions?

Depending….

What type of gases can SonicView detect?

The camera does not detect gases directly but the sound leaks make when the gas is escaping (learn more about technology). Vacuum leaks can also be detected because they create turbulences and thus ultrasounds. What is needed is a minimum pressure difference (typically 50 mbar / 0.7 psi) and a path in the air for the sound to propagate.

To what maximal distance can SonicView detect leaks?

Depending on the flow rate of the leak, from 30 centimeters (1 feet) to 50-100 meters (150-300 feet). Large leaks (thousand of liters per hour) can be detected up to 50 meters. Small leaks (a few liters per hour) are detectable at a few meters. Typical leak search distance is between 1 to 6 meters (3 to 20 feet).

Can I see the gas leak location?

Ultra Pro filters all noises outside the detection window, in particular low frequency in the audible range. Even in a very noisy environment like in gas turbine noise enclosure with up to 100 dB(A) noise, leakages have been detected.

Ultra Pro estimates in real-time its lower limit of detection (LoD), allowing the user to know how accurate the inspection is. This is typically useful when acceptance criterion is used.

How are Distran's solutions not affected by false positives?

Direct sight is not required for leak detection, but the sound must propagate from the leak to the surface of Ultra Pro, where the microphones are located. This is typically not the case for underground systems (shielded by soil). For insulated systems it depends on how tight the insulation is.

How can I connect the camera to my actual gas detection system?

Similar to an optical camera, the accuracy is determined as an angle (the closer you are to a leak, the smaller is the linear accuracy). The accuracy depends on the acoustic imaging algorithm, the imaging frequency and how good the optical camera and the microphone array are matched.

The typical accuracy is about 1°.

???

…..

???

….

What is the difference between Distran’s portable and fixed solutions?

What is Distran’s Acoustic Leak Imaging (ALI) technology?

What type of gases can SonicView detect?

To what maximal distance can SonicView detect leaks?

Can I see the gas leak location?

How is Acoustic Leak Imaging (ALI) different from traditional point gas detectors or fixed gas detectors?

How is Acoustic Leak Imaging (ALI) different from traditional single microphone detectors (UGLD)?

How are Distran's solutions not affected by false positives?

Can the camera be mounted outdoors?

Does it work in all weather or lighting conditions?

Does SonicView require regular calibration?

How can I connect the camera to my actual gas detection system?

How can I visualize leaks, do I need an additional software?

Can I replay the leak footage after an alert is triggered?

Is technical support or training available?

Ready to upgrade to Sonic safety?

Claudio Fecarotta

Business Development Manager

Fixed Detection

Hermann Préchoux

Business Development Manager

Fixed Detection