More safety and reliability for upstream, midstream, and downstream

Equipment-intensive and highly regulated processes drive operations in Oil & Gas companies. The detection of gas leaks is key to protecting people, assets, and the planet.

Professionals in commissioning, maintenance, HSE (health, safety, and environment), and other fields trust in Distran along the entire value chain.

Browse the sections below to learn more about:

![]() How our acoustic imagers enable inspections for all kinds of gas leaks in all parts of onshore and offshore sites.

How our acoustic imagers enable inspections for all kinds of gas leaks in all parts of onshore and offshore sites.

![]() How midstream facilities count on Distran to mitigate climate change by reducing fugitive methane emissions.

How midstream facilities count on Distran to mitigate climate change by reducing fugitive methane emissions.

![]() How our ultrasonic cameras make commissioning, turnarounds, and regular leak detection and repair (LDAR) programs faster, safer, and more reliable.

How our ultrasonic cameras make commissioning, turnarounds, and regular leak detection and repair (LDAR) programs faster, safer, and more reliable.

Gas leak detection with ultrasonic cameras in the Oil & Gas Industry

More safety and reliability for upstream, midstream, and downstream

Equipment-intensive and highly regulated processes drive operations in Oil & Gas companies. The detection of gas leaks is key to protecting people, assets, and the planet.

Professionals in commissioning, maintenance, HSE (health, safety, and environment), and other fields trust in Distran along the entire value chain.

Browse the sections below to learn more about:

![]() How our acoustic imagers enable inspections for all kinds of gas leaks in all parts of onshore and offshore sites.

How our acoustic imagers enable inspections for all kinds of gas leaks in all parts of onshore and offshore sites.

![]() How midstream facilities count on Distran to mitigate climate change by reducing fugitive methane emissions.

How midstream facilities count on Distran to mitigate climate change by reducing fugitive methane emissions.

![]() How our ultrasonic cameras make commissioning, turnarounds, and regular leak detection and repair (LDAR) programs faster, safer, and more reliable.

How our ultrasonic cameras make commissioning, turnarounds, and regular leak detection and repair (LDAR) programs faster, safer, and more reliable.

What our customers say

An indispensable tool for onshore & offshore operations:

An indispensable tool for onshore & offshore operations:

“Inspections are carried out remotely, easily, quickly, and, above all, safely. The Ultra Pro X has become an indispensable tool.”

Vincent Leleux

Deputy Head of Operations at

TotalEnergies Feyzin, France

“With Ultra Pro X, inspectors can cover more ground at once and detect leaks faster in hard-to-reach areas without scaffolding.”

TotalEnergies FPSOs

Gulf of Guinea,

Africa

“We can pick up the smallest of sounds. It saves our teams a lot of time while making sure the system is safe and leak-tight.”

Chris Anderson

Subsea Project Engineer at

Shell, United States

6 improvements for operation and maintenance programs in the Oil & Gas industry

How does Distran streamline gas leak detection?

How does Distran streamline gas leak detection?

INCREASED SAFETY

With a working distance from 0.3 – 100 m (1 – 330 ft), operators avoid contact with the gas and the need for scaffolding.

REDUCED DOWNTIME

Inspection teams cover large areas in little time and hence reduce downtime due to planned and unplanned shutdowns.

FASTER TRAINED STAFF

As no expert know-how is required, new users get familiar with the Distran ultrasonic camera quickly, which further saves costs.

CUT EMISSIONS

The leak rate quantification enables to prioritize maintenance activities based on the impact of the leak, helping cut fugitive emissions.

COMPREHENSIVE INSPECTIONS

Distran ultrasonic imagers help expand the scope of inspections because Acoustic Leak Imaging devices detect leaks of all gas types.

USE IN HAZARDOUS AREAS

The intrinsically safe Distran Ultra Pro X can be used for detecting gas leaks in potentially explosive areas.

Improve your facility’s safety and decrease turnaround and start-up time with Distran Ultra Pro X.

Upstream operations

Protection of people and assets onshore and offshore

Video: Methane Leak detected by the Distran Ultrasound camera – At TotalEnergies’ Egina FPSO

Exposed to challenging conditions, upstream operations mainly include exploration and production activities on land and on water. For instance, Floating Production Storage Offloading (FPSO) units comprise tight piping networks to process oil and gas extracted from subsea reservoirs.

Undetected leaks may lead to the release of dangerous gases, compromise the safety of workers, and cause safety-relevant equipment failures. Our upstream customers typically use an intrinsically safe leak detection device during startups/ turnarounds and regular leak surveys.

As a preventative maintenance tool, the Ultra Pro X detects leaks of all gas types that are commonly found at upstream facilities. This includes methane, nitrogen, CO2, inergen, and compressed air. The Ex-proof device allows operators to inspect large hazardous, noisy, and hard-to-reach areas without scaffolding.

With the right gas leak detection in place, upstream companies can focus on increasing safety and performance. Distran’s mission is to empower our customer to focus on their asset performance – instead of dealing with the consequences of undetected leaks.

Upstream operations

Protection of people and assets onshore and offshore

Video: Methane Leak detected by the Distran Ultrasound camera – At TotalEnergies’ Egina FPSO

Exposed to challenging conditions, upstream operations mainly include exploration and production activities on land and on water. For instance, Floating Production Storage Offloading (FPSO) units comprise tight piping networks to process oil and gas extracted from subsea reservoirs.

Undetected leaks may lead to the release of dangerous gases, compromise the safety of workers, and cause safety-relevant equipment failures. Our upstream customers typically use an intrinsically safe leak detection device during startups/ turnarounds and regular leak surveys.

As a preventative maintenance tool, the Ultra Pro X detects leaks of all gas types that are commonly found at upstream facilities. This includes methane, nitrogen, CO2, inergen, and compressed air. The Ex-proof device allows operators to inspect large hazardous, noisy, and hard-to-reach areas without scaffolding.

With the right gas leak detection in place, upstream companies can focus on increasing safety and performance. Distran’s mission is to empower our customer to focus on their asset performance – instead of dealing with the consequences of undetected leaks.

DOWNLOAD OUR BROCHURE: ENSURE SAFETY & OPERATIONAL RELIABILITY WITH ULTRA PRO X

Streamline gas leak detection in complex and tough offshore environments

Midstream operations

A cost-effective way of reducing fugitive emissions

Midstream companies operate pipelines and transmission facilities to move and distribute oil & gas from upstream to downstream. The processing of liquified natural gas (LNG) is another key midstream operation. In terms of Oil & Gas industry regulatory compliance, the reduction of fugitive emissions from methane (CH4) leaks is crucial.

Video: Methane Leak detected by the Distran Ultrasound camera – Outdoors, on a substation

Transmission System Operators (TSO) often use a combination of different gas leak detection technologies. Many use Distran ultrasonic cameras to detect leaks of various gas types (methane, air, etc.) at pressure-reducing (sub)stations, interconnection stations, and storage & distribution sites.

Video: Small methane Leak detected by the Distran Ultrasound camera – On a compressor station

Other technologies such as Optical Gas Imaging (OGI) cameras work well for the detection of hydrocarbons. Ultrasonic cameras detect any kind of gas leaks and quantify the leak rate in real time, enabling operators to prioritize maintenance activities based on factors such as size, location, and ecological impact of the detected leaks. Some companies combine the two technologies.

To mitigate climate change, governments and international organizations push for new regulations on methane emissions. They are expected to require that oil and gas companies implement LDAR programs to ensure compliance.

Video: View of the same methane leak on a connector, within a refinery, by the Distran ultrasound camera and by an OGI camera

Midstream operations

A cost-effective way of reducing fugitive emissions

Video: Methane Leak detected by the Distran Ultrasound camera – Outdoors, on a substation

Midstream companies operate pipelines and transmission facilities to move and distribute oil & gas from upstream to downstream. The processing of liquified natural gas (LNG) is another key midstream operation. In terms of Oil & Gas industry regulatory compliance, the reduction of fugitive emissions from methane (CH4) leaks is crucial.

Video: Small methane Leak detected by the Distran Ultrasound camera – On a compressor station

Transmission System Operators (TSO) often use a combination of different gas leak detection technologies. Many use Distran ultrasonic cameras to detect leaks of various gas types (methane, air, etc.) at pressure-reducing (sub)stations, interconnection stations, and storage & distribution sites.

Video: View of the same methane leak on a connector, within a refinery, by the Distran ultrasound camera and by an OGI camera

Other technologies such as Optical Gas Imaging (OGI) cameras work well for the detection of hydrocarbons. Ultrasonic cameras detect any kind of gas leaks and quantify the leak rate in real time, enabling operators to prioritize maintenance activities based on factors such as size, location, and ecological impact of the detected leaks. Some companies combine the two technologies.

To mitigate climate change, governments and international organizations push for new regulations on methane emissions. They are expected to require that oil and gas companies implement LDAR programs to ensure compliance.

Downstream operations

The fast track to avoid downtime and maximize uptime

Downtime and even more unscheduled downtime are major concerns for downstream companies. Our acoustic cameras support refineries, petrochemical plants, and other downstream installations in both avoiding unplanned downtime and shortening scheduled downtime.

Regular turnarounds take place for legal (compliance), technical (safety), and economic (lifetime of assets) reasons. Like during commissioning, the teams in charge use our non-destructive testing (NDT) devices to check for various types of leaks (air, nitrogen, and hydrocarbons) during tightness testing. The ability to detect all types of gas leaks is a powerful feature to speed up startup processes and save time as well as money.

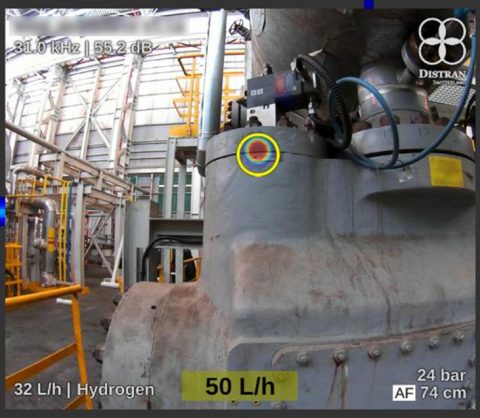

In addition to maintaining safety standards, leak detection and repair (LDAR) programs aim to prevent unplanned shutdowns during day-to-day operations with our cameras. Potentially leaking components that contain air, nitrogen, methane, hydrogen, acetylene, and many other gases, undergo frequent inspections. The faster, the safer, the easier – the better.

The leak rate quantification module of Distran acoustic cameras enables operators in all segments of Oil & Gas to streamline maintenance. With the integrated reporting tool Audalytics, our customers include leak rates, videos, and images in reports, classifying leaks and monitoring assets over time.

Detection of methane leaks

Reduce methane emissions and keep up with new EU regulations.

Detection of hydrogen leaks

Ensure the safety of people and assets with easy detection of explosive gases.

Detection of vacuum leaks

Ensure process quality and decrease production costs by detection vacuum leaks.

Customer Testimonial

SHELL

An efficient solution for refinery inspections

“Distran makes it possible to significantly expand the spectrum of leakage identification.

This can be a key factor on the way to a safe production facility.”

Daniel Blambeck, Team Lead Planning –

Plant Engineer, Shell Energy and Chemicals Park Rheinland

Customer Testimonial

SHELL

An efficient solution for refinery inspections

“Distran makes it possible to significantly expand the spectrum of leakage identification.

This can be a key factor on the way to a safe production facility.”

Daniel Blambeck, Team Lead Planning – Plant Engineer, Shell Energy and Chemicals Park Rheinland

–

Contact us

We will be more than happy to advise you on the best solution for your gas leak detection challenges!