Acoustic Leak Imaging for the Chemical Industry

More uptime with less effort

Gas leaks in chemical and pharmaceutical plants can pose serious challenges—affecting safety, causing costly downtime, compromising product quality, and increasing emissions. Detecting leaks in complex systems, noisy environments, and hazardous areas can be difficult and time-consuming, putting operations and compliance at risk.

The Distran Ultra Pro X tackles these challenges with fast, precise, leak detection of any gas type, including vacuum leaks—all from a safe distance. The camera also enables quantification of leak rates. Its integrated Audalytics software simplifies reporting, allowing teams to categorize leaks by severity and make data-driven maintenance decisions.

Enhance safety, efficiency, and compliance with the latest leak detection technology.

What our customers say

Cutting inspection time from days to hours:

Cutting inspection time from days to hours:

“An entire site can be surveyed up to 3 times faster with the Ultra Pro than with soap spray. Comprehensive, proactive leak inspections are now performed every 4 months.”

Chemical plant’s R&D team

“Detecting hydrogen leaks used to take us 4 to 5 days, with the Distran camera, 2 to 3 hours are enough.”

Bernard Favard,

Technical Operations Manager ATE

Arkema Mont, France

“A leak was clearly visible through the Ultra Pro camera at a vacuum pump coupling. This leakage point would have gone unnoticed without this device.”

Thomas R.,

Process Engineer – Bostik Ribécourt, France

Gas leak detection

Overcoming challenges in Chemical & Pharma production

6 advantages for the Chemical Industry by using Distran ultrasonic cameras

Why do chemical plants detect gas and vacuum leaks with Distran?

Why do chemical plants detect gas and vacuum leaks with Distran?

CHEMICAL PLANT SAFETY

Distran ultrasonic cameras do not require contact with the gas. They allow for detecting leaks from 0.3 – 100 m (1 – 330 ft), making climbing aids unnecessary.

PRODUCT QUALITY

Compared to other approaches such as soap spray or sniffers, our devices detect vacuum and gas leaks up to 10x faster, improving product quality.

QUICK INSTRUCTIONS

After a 15-minute introduction, new users are ready to start detecting gas leaks with our single-handed, intuitive acoustic cameras.

EFFECTIVE REPAIRS

Combining the built-in reporting tool with the leak rate quantification feature, priorities can be set for repairs based on various data.

PROCESS RELIABILITY

Detecting vacuum and gas leaks more quickly and safely, our single-handed acoustic cameras help keep plants running and make production more reliable.

INTRINSIC SAFETY

The Ultra Pro X is an intrinsically safe leak detection camera for use in hazardous locations and is compliant with ATEX, IECEx and UL standards.

Ensure chemical and pharmaceutical production performance and worker’s safety with Distran Ultra Pro X ultrasonic camera.

Detection of leaks of hazardous gases in hard-to-reach areas

A proven preventative maintenance tool

Previously, leak detection activities required a lot of energy consumption, human resources, scaffolding, time, and ultimately costs. For instance, to search a tank for leaks by soaping it up, could take weeks. For reasons often related to safety regulations, it was much more difficult to check for leaks during normal operations.

Different from traditional leak detection technologies such as soap spray and sniffers, Distran’s approach is based on Acoustic Leak Imaging. Detecting the specific sounds vacuum and gas leaks generate, our devices allow for searching for leaks from safe distances and regardless of the type of gas.

Chemical plants benefit from this new approach, as they can reduce the material, staff, time, and ultimately costs of inspections. Even if they check for small leaks of toxic or explosive gases, it is much easier to align safety concerns with reliability goals.

Therefore, the Ex-proof Distran ultrasonic camera has proven to be especially effective for the detection of hazardous gases such as hydrogen and acetylene.

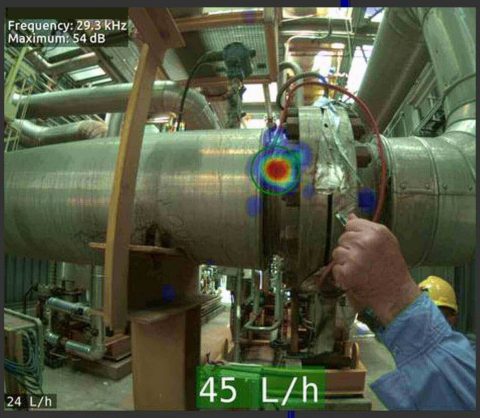

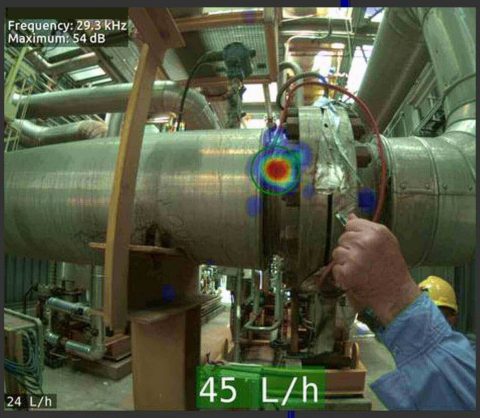

Video: Dual vacuum leak on joint

Vacuum leak

on a esterification reactor

Acetylene leak

on a bottle connection

Synthetic gas leak

on a welded flange

Detection of leaks of hazardous gases in hard-to-reach areas

A proven preventative maintenance tool

Video: Dual vacuum leak on joint

Previously, leak detection activities required a lot of energy consumption, human resources, scaffolding, time, and ultimately costs. For instance, to search a tank for leaks by soaping it up, could take weeks. For reasons often related to safety regulations, it was much more difficult to check for leaks during normal operations.

Different from traditional leak detection technologies such as soap spray and sniffers, Distran’s approach is based on Acoustic Leak Imaging. Detecting the specific sounds vacuum and gas leaks generate, our devices allow for searching for leaks from safe distances and regardless of the type of gas.

Chemical plants benefit from this new approach, as they can reduce the material, staff, time, and ultimately costs of inspections. Even if they check for small leaks of toxic or explosive gases, it is much easier to align safety concerns with reliability goals.

Therefore, the Ex-proof Distran ultrasonic camera has proven to be especially effective for the detection of hazardous gases such as hydrogen and acetylene.

Vacuum leak

on a esterification reactor

Acetylene leak

on a bottle connection

Synthetic gas leak

on a welded flange

Intuitive, easy-to-use devices to ensure product quality

A gas leak detection tool for anyone

Video: Nitrogen leak found via its echo on the floor in a chemical plant

Technologies that require expert know-how can be a tricky bottleneck. In particular, when undetected leaks pose a danger to people and call for immediate action. Distran’s acoustic cameras help solve this issue, as it takes only a short introduction to use them in the field.

Regardless of whether a plant’s own specialists or an external service provider is in charge of conducting the inspections, typically a large number of operators use our devices. Thanks to this user-independent approach, the plants decrease costs without decreasing safety and reliability.

Service providers not only benefit from the ease of use compared to other technologies. Distran cameras also open the door to diversifying their product portfolio, offering more comprehensive and more efficient services for the detection of gas leaks.

Since its foundation in 2013, Distran has been committed to innovating the way our customers detect vacuum and gas leaks, improve process safety, and ensure product quality as well as regulatory compliance. We continue our mission, as we continuously improve existing and develop new solutions.

Intuitive, easy-to-use devices to ensure product quality

A gas leak detection tool for anyone

Video: Nitrogen leak found via its echo on the floor in a chemical plant

Technologies that require expert know-how can be a tricky bottleneck. In particular, when undetected leaks pose a danger to people and call for immediate action. Distran’s acoustic cameras help solve this issue, as it takes only a short introduction to use them in the field.

Regardless of whether a plant’s own specialists or an external service provider is in charge of conducting the inspections, typically a large number of operators use our devices. Thanks to this user-independent approach, the plants decrease costs without decreasing safety and reliability.

Service providers not only benefit from the ease of use compared to other technologies. Distran cameras also open the door to diversifying their product portfolio, offering more comprehensive and more efficient services for the detection of gas leaks.

Since its foundation in 2013, Distran has been committed to innovating the way our customers detect vacuum and gas leaks, improve process safety, and ensure product quality as well as regulatory compliance. We continue our mission, as we continuously improve existing and develop new solutions.

–

Contact us

We will be more than happy to advise you on the best solution for your gas leak detection challenges!