How it works

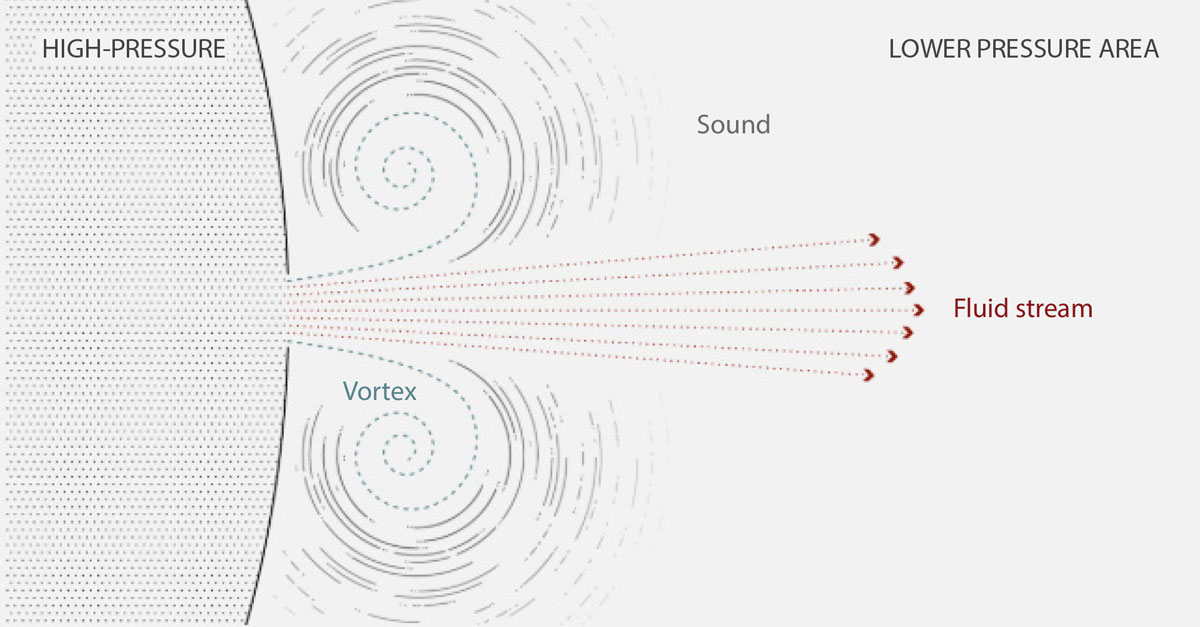

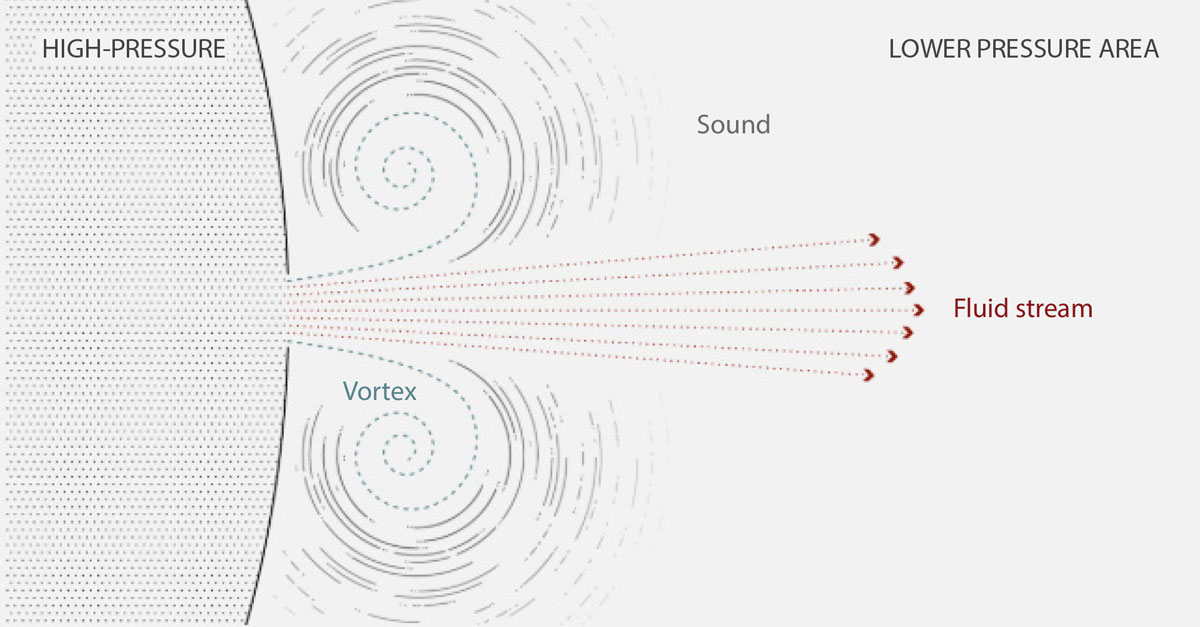

Many physical processes, such as gas leaks, partial discharges or mechanical defects, create acoustic emissions (AE). Ultrasounds are often the first indication that an element is starting to fail, well before heat/infrared emissions (if any).

Why do gas leaks produce ultrasounds?

How does it work

Many physical processes, such as gas leaks, partial discharges or mechanical defects, create acoustic emissions (AE). Ultrasounds are often the first indication that an element is starting to fail, well before heat/infrared emissions (if any).

How does ultrasound imaging work

From sounds to images

The surface of the Distran ultrasound cameras comprises dozens of sensors that measure the sound field. When an ultrasound wave hits the surface, each sensor detects it at a different time. These differences are used to locate the ultrasound sources and overlay their location on a video image.

- Detect any gas type, even compressed air, vacuum, and steam leaks.

- Pinpoint gas leaks without scanning each single element.

- Take into account an unlimited number of sources simultaneously.

How does ultrasound imaging work

From sounds to images

The surface of the Distran ultrasound cameras comprises dozens of sensors that measure the sound field. When an ultrasound wave hits the surface, each sensor detects it at a different time. These differences are used to locate the ultrasound sources and overlay their location on a video image.

- Detect any gas type, even compressed air, vacuum, and steam leaks.

- Pinpoint gas leaks without scanning each single element.

- Take into account an unlimited number of sources simultaneously.

DeepRange:

Extended sensitivity to reveal smaller leaks in noisy environments… that others miss!

Quantification of gas leak rate

From sounds to gas leak rate

In addition to locating the leak, Ultra Pro is able to estimate the flow escaping through a leak in liters per hour, based on the acoustic emission strength and the pressure difference at the leak. This allows the user to quickly asses the severity and the cost associated with the leak. Furthermore, the smallest detectable leak in the current environment is automatically displayed in real-time (patent pending).

Quantification of gas leak rate

From sounds to gas leak rate

In addition to locating the leak, Ultra Pro is able to estimate the flow escaping through a leak in liters per hour, based on the acoustic emission strength and the pressure difference at the leak. This allows the user to quickly asses the severity and the cost associated with the leak. Furthermore, the smallest detectable leak in the current environment is automatically displayed in real-time (patent pending).