29 Jan Innovation driving performance at Bugey Nuclear Power Plant, France

Acoustic imaging serving nuclear power plants – episode 2

Innovation driving performance at Bugey Nuclear Power Plant, France

As part of its operational excellence and safety strategy, the Bugey, France Nuclear Power Plant has integrated the Distran ultrasonic camera into its periodic inspections of the alternator hydrogen cooling circuit.

Distran acoustic imaging technology provides several key benefits:

![]() Contactless inspection in complete safety, even in areas with restricted access.

Contactless inspection in complete safety, even in areas with restricted access.

![]() Accurate and immediate localization of anomalies, without complex interpretation.

Accurate and immediate localization of anomalies, without complex interpretation.

![]() Significant time savings during periodic tests and maintenance operations.

Significant time savings during periodic tests and maintenance operations.

![]() Improved reliability and confidence in inspection results.

Improved reliability and confidence in inspection results.

![]() Maintained availability of installations, in compliance with the most stringent standards of the nuclear industry.

Maintained availability of installations, in compliance with the most stringent standards of the nuclear industry.

Acoustic imaging serving nuclear power plants – episode 2

Innovation driving performance at Bugey Nuclear Power Plant, France

As part of its operational excellence and safety strategy, the Bugey, France Nuclear Power Plant has integrated the Distran ultrasonic camera into its periodic inspections of the alternator hydrogen cooling circuit.

Distran acoustic imaging technology provides several key benefits:

- Contactless inspection in complete safety, even in areas with restricted access.

- Accurate and immediate localization of anomalies, without complex interpretation.

- Significant time savings during periodic tests and maintenance operations.

- Improved reliability and confidence in inspection results.

- Maintained availability of installations, in compliance with the most stringent standards of the nuclear industry.

Presentation of the Bugey Nuclear Power Plant

The EDF Bugey Nuclear Power Plant, situated near Lyon, France, plays a crucial role in the French energy mix. With its four 900-MW reactors, it produces an average of 20 TWh per year, equivalent to one-third of the electricity consumption of 8.2 million inhabitants in this region.

Fundamental Operating Principles

The Bugey site is a low-carbon, reliable, and high-performance electricity generation facility. Availability, safety, and water management are its main priorities. This requirement is supported by continuous monitoring of equipment and anticipation of any anomaly.

Since 2022, the plant has integrated Distran acoustic imaging cameras into its inspections to further enhance the reliability of its controls.

“At Bugey, we continuously pursue innovation and operational excellence,

aimed at sustainably strengthening the reliability and safety

of our installations while optimizing our operations.

It is in this context that we discovered

Distran’s acoustic imaging technology.

The initial trials quickly confirmed its operational

relevance and its tangible contribution for field teams.”

“At Bugey, we continuously pursue innovation and operational excellence, aimed at sustainably strengthening the reliability and safety of our installations while optimizing our operations.

It is in this context that we discovered Distran’s acoustic imaging technology.

The initial trials quickly confirmed its operational relevance and its tangible contribution for field teams.”

Ingrid CÔTE-LOEFFEL

DGP-PMO – Operational Excellence

EDF – Direction Production Nucléaire

Monitoring what matters most: A strategic system under close surveillance

Within a nuclear power plant, every component contributes to overall safety. Many pieces of equipment must always be available and in perfect operating condition.

This is particularly true of the alternator, an essential piece of equipment that significantly impacts plant availability due to its crucial role in converting mechanical energy into electrical energy. Its availability is essential, and its maintenance costs justify increased monitoring of all associated systems.

The alternator, which generates significant heat, is equipped with a hydrogen cooling circuit. The reliability of this circuit is assessed through periodic tests designed to verify the integrity of all components and the system’s tightness.

The acceptance criteria applied are particularly strict: any anomaly, even a minor one, may lead to a turbine shut down for maintenance and disconnection from the power grid. To ensure safe alternator operation, strict thresholds are observed, including a maximum allowable hydrogen leak flow rate.

Until recently, teams responsible for periodic testing used hydrogen concentration sensors to detect potential tightness defects in the circuit. Without precise information on the location of the defect, additional investigations were required under operational time pressure, involving multiple stakeholders and extending diagnostic timelines.

The need for a reliable, fast, and accurate leak pinpointing method, usable in hazardous areas and suited to noisy, ventilated, and difficult-to-access environments, quickly became evident.

Monitoring what matters most:

A strategic system under close surveillance

Within a nuclear power plant, every component contributes to overall safety. Many pieces of equipment must always be available and in perfect operating condition.

This is particularly true of the alternator, an essential piece of equipment that significantly impacts plant availability due to its crucial role in converting mechanical energy into electrical energy. Its availability is essential, and its maintenance costs justify increased monitoring of all associated systems.

The alternator, which generates significant heat, is equipped with a hydrogen cooling circuit. The reliability of this circuit is assessed through periodic tests designed to verify the integrity of all components and the system’s tightness.

The acceptance criteria applied are particularly strict: any anomaly, even a minor one, may lead to a turbine shut down for maintenance and disconnection from the power grid. To ensure safe alternator operation, strict thresholds are observed, including a maximum allowable hydrogen leak flow rate.

Until recently, teams responsible for periodic testing used hydrogen concentration sensors to detect potential tightness defects in the circuit. Without precise information on the location of the defect, additional investigations were required under operational time pressure, involving multiple stakeholders and extending diagnostic timelines.

The need for a reliable, fast, and accurate leak pinpointing method, usable in hazardous areas and suited to noisy, ventilated, and difficult-to-access environments, quickly became evident.

Key Challenges of Anomaly Detection in Nuclear Power Plants

ENSURING PERSONNEL

SAFETY

GUARANTEEING INSTALLATION SAFETY

MAINTAINING INSTALLATION

AVAILABILITY

Periodic testing: Acoustic imaging deployed on the alternator

The search for tightness defects, even the smallest ones, is a critical part of preventive maintenance programs. Indeed, a loss of pressure can cause malfunctions that may, in some cases, trigger the automatic shutdown of a reactor.

Nothing is therefore left to chance: every loss, whether air or steam, is rigorously investigated. Meanwhile, parasitic air ingress (or vacuum leaks) is closely monitored due to its impact on plant efficiency and its role in corrosion phenomena.

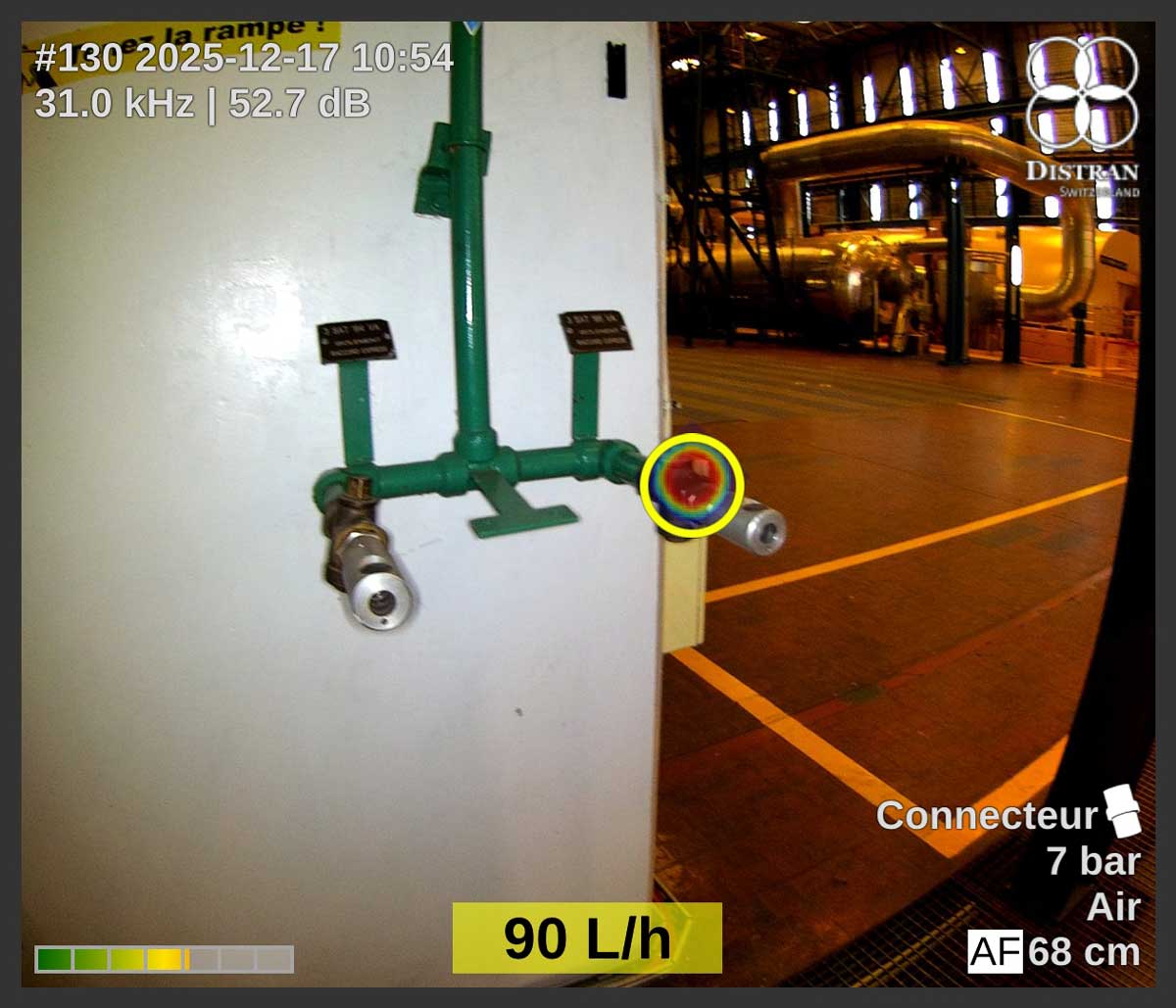

In December 2024, during a periodic test, a slight deviation, only a few Normal Cubic Meters per day (Nm³/day) above the usual consumption threshold of the alternator circuit, triggered a targeted inspection campaign of auxiliary circuits.

The use of the Distran Ultra Pro X ultrasonic camera enabled the precise location of a tightness defect on a sight glass of a pressurized compartment within moments, providing an immediate diagnosis and rapid corrective action while preserving system safety and availability.

The search for tightness defects, even the smallest ones, is a critical part of preventive maintenance programs. Indeed, a loss of pressure can cause malfunctions that may, in some cases, trigger the automatic shutdown of a reactor.

Nothing is therefore left to chance: every loss, whether air or steam, is rigorously investigated. Meanwhile, parasitic air ingress (or vacuum leaks) is closely monitored due to its impact on plant efficiency and its role in corrosion phenomena.

In December 2024, during a periodic test, a slight deviation, only a few Normal Cubic Meters per day (Nm³/day) above the usual consumption threshold of the alternator circuit, triggered a targeted inspection campaign of auxiliary circuits.

The use of the Distran Ultra Pro X ultrasonic camera enabled the precise location of a tightness defect on a sight glass of a pressurized compartment within moments, providing an immediate diagnosis and rapid corrective action while preserving system safety and availability.

Leaks detected by Ultra Pro X within French nuclear facilities

Detection of

a tightness defect

System’s

tightness confirmation

Detection of

partial discharge

“The Distran camera has completely changed the way we approach periodic testing.

On the alternator cooling circuit, it enabled us to locate a tightness defect within a few minutes, which would have taken us hours to identify.

It’s a real gain in time, safety, and confidence in our diagnostics.”

Gilles GUÉRARD

Reliability Management Department, Air/Ventilation systems engineer

EDF Bugey Nuclear Power Plant

“The Distran camera has completely changed the way we approach periodic testing.

On the alternator cooling circuit, it enabled us to locate a tightness defect within a few minutes, which would have taken us hours to identify.

It’s a real gain in time, safety, and confidence in our diagnostics.”

Gilles GUÉRARD

Reliability Management Department, Air/Ventilation systems engineer

EDF Bugey Nuclear Power Plant

Concrete results, integrated into Bugey site’s maintenance standards

The rapid and precise detection of the tightness defect location, combined with the replacement of the faulty component within just a few hours, helped limit downtime. For reference, each hour of lost production is equivalent to approximately €60,000.

Building on this experience, the Bugey Nuclear Power Plant decided to integrate the Distran Ultra Pro X ultrasonic camera into its periodic testing procedures as a systematic means of anomaly detection on alternator circuits.

Ultrasonic acoustic imaging technology offers numerous advantages for detecting tightness defects in pressurized or vacuum networks and equipment:

- Immediate diagnosis, without relying on external resources whose mobilization may take time.

- Remote, multidirectional inspection without contact with equipment or the need for scaffolding or lifts.

- Instant visual localization of the defect and estimation of its severity.

- Incident monitoring and post-repair validation directly on site.

- Compatibility with all types of pressurized gases as well as vacuum systems.

- Simple, intuitive operation accessible to any operator without advanced expertise.

- Replacement of empirical methods or approaches unsuited to the nuclear environment.

Concrete results, integrated into Bugey site’s maintenance standards

The rapid and precise detection of the tightness defect location, combined with the replacement of the faulty component within just a few hours, helped limit downtime. For reference, each hour of lost production is equivalent to approximately €60,000.

Building on this experience, the Bugey Nuclear Power Plant decided to integrate the Distran Ultra Pro X ultrasonic camera into its periodic testing procedures as a systematic means of anomaly detection on alternator circuits.

Ultrasonic acoustic imaging technology offers numerous advantages for detecting tightness defects in pressurized or vacuum networks and equipment:

- Immediate diagnosis, without relying on external resources whose mobilization may take time.

- Remote, multidirectional inspection without contact with equipment or the need for scaffolding or lifts.

- Instant visual localization of the defect and estimation of its severity.

- Incident monitoring and post-repair validation directly on site.

- Compatibility with all types of pressurized gases as well as vacuum systems.

- Simple, intuitive operation accessible to any operator without advanced expertise.

- Replacement of empirical methods or approaches unsuited to the nuclear environment.

Improved

inspection reliability

Instant visualization quickly eliminates uncertainty regarding the origin of an anomaly.

Reduced

intervention time

Inspections are faster and analyses more targeted.

Enhanced

safety

Contactless detection limits exposure and enables remote operation.

Improved

installation availability

By precisely locating the intervention area, repairs can be carried out in a targeted manner without a full shutdown of the turbo-alternator unit.

A proven technology serving safety and availability

By integrating Distran acoustic imaging cameras into its periodic testing methodology, the Bugey plant has equipped itself with an additional tool to meet the dual requirement of nuclear safety and continuity of power supply to the grid.

The experience gained from the alternator cooling circuit fully illustrates the relevance and reliability of Distran technology, which is perfectly suited to the operational needs of power plant operators seeking to combine prevention, responsiveness, and long-term performance.

A proven technology serving safety and availability

By integrating Distran acoustic imaging cameras into its periodic testing methodology, the Bugey plant has equipped itself with an additional tool to meet the dual requirement of nuclear safety and continuity of power supply to the grid.

The experience gained from the alternator cooling circuit fully illustrates the relevance and reliability of Distran technology, which is perfectly suited to the operational needs of power plant operators seeking to combine prevention, responsiveness, and long-term performance.

“The ability of the Distran camera to rapidly and confidently identify

the source of a deviation is a key lever for maintaining control

over installations and ensuring system safety at the Bugey Nuclear Power Plant.

Beyond its ease of use, the Distran camera provides teams

with a level of precision and reliability that enhances the quality of on-site diagnostics.”

The ability of the Distran camera to rapidly and confidently identify the source of a deviation is a key lever for maintaining control over installations and ensuring system safety at the Bugey Nuclear Power Plant.

Beyond its ease of use, the Distran camera provides teams with a level of precision and reliability that enhances the quality of on-site diagnostics.”

Ingrid CÔTE-LOEFFEL

DGP-PMO – Operational Excellence

EDF – Direction Production Nucléaire