03 Apr How Arkema cuts gas leak inspection time from days to hours

Arkema Sucess Story

How Arkema cuts gas leak inspection time from days to hours

Highlights:

![]() Average inspection time before Distran: 5 DAYS. With Distran: 3 HOURS.

Average inspection time before Distran: 5 DAYS. With Distran: 3 HOURS.

![]() Hydrogen, steam, and vacuum leaks detected by a single device.

Hydrogen, steam, and vacuum leaks detected by a single device.

![]() Operations team performance and responsiveness have significantly improved.

Operations team performance and responsiveness have significantly improved.

Arkema Sucess Story

How Arkema cuts gas leak inspection time from days to hours

Highlights:

![]() Average inspection time before Distran: 5 DAYS. With Distran: 3 HOURS.

Average inspection time before Distran: 5 DAYS. With Distran: 3 HOURS.

![]() Hydrogen, steam, and vacuum leaks detected by a single device.

Hydrogen, steam, and vacuum leaks detected by a single device.

![]() Operations team performance and responsiveness have significantly improved.

Operations team performance and responsiveness have significantly improved.

Arkema is a global specialty chemicals and advanced materials company headquartered in France. It operates in various sectors, including coatings, adhesives, construction materials, and high-performance polymers. Arkema focuses on innovation and sustainability, developing products that enhance performance and reduce environmental impact. The company serves various industries, such as automotive, electronics, packaging, and consumer goods, and is known for its expertise in advanced materials and chemical solutions.

Arkema Mont, France, has several production units with complex processes for designing innovative, high-performance products. They require the use of highly reliable tools.

Since 2022, the operations team has depended heavily on the Distran Ultra Pro X acoustic camera to detect, pinpoint, and quantify leaks.

“We went from spending up to 5 DAYS inspecting

carbon nanotube reactors for hydrogen leaks to 3 HOURS.”

Bernard Favard

Technical Operations Manager ATE, Arkema

Leak detection is crucial for the Arkema Mont operations team

for several reasons:

Leak detection is crucial for the Arkema Mont operations team

for several reasons:

SAFETY

Prompt leak detection helps prevent hazardous chemical spills, which can pose severe risks to worker safety and public health. It is crucial, given Arkema’s handling of potentially dangerous chemicals and materials.

ENVIRONMENTAL PROTECTION

Preventing leaks helps minimize the release of harmful substances into the environment, aligning with Arkema’s commitment to sustainability and reducing its ecological footprint.

REGULATORY COMPLIANCE

Stringent regulations govern the handling and storage of chemicals. Effective leak detection ensures compliance with these regulations, helping Arkema avoid penalties.

COST SAVINGS

Identifying and addressing leaks early can prevent costly damage to equipment, reduce waste of valuable raw materials, and avoid more extensive (and expensive) interventions.

OPERATIONAL EFFICIENCY

Leaks interfere with the integrity of production processes. Proactive leak inspections are necessary to ensure seamless operations without unexpected interruptions.

COMMITMENT TO SUSTAINABILITY

Proactively managing leaks and their potential impacts helps Arkema demonstrate its commitment to being a responsible and reliable chemical company.

Improved site’s responsiveness and performance

Improved site’s responsiveness and performance

Leak inspections used to be slow and cumbersome. Arkema’s teams have significantly reduced response times during interventions thanks to the Ultra Pro X.

Bernard Favard is Arkema’s Technical Operations Manager ATE based in Mont. He’s been involved in the Distran deployment from the beginning.

“We have significantly improved our performance using the Distran camera,” says Favard.

Here are three examples, courtesy of our clients:

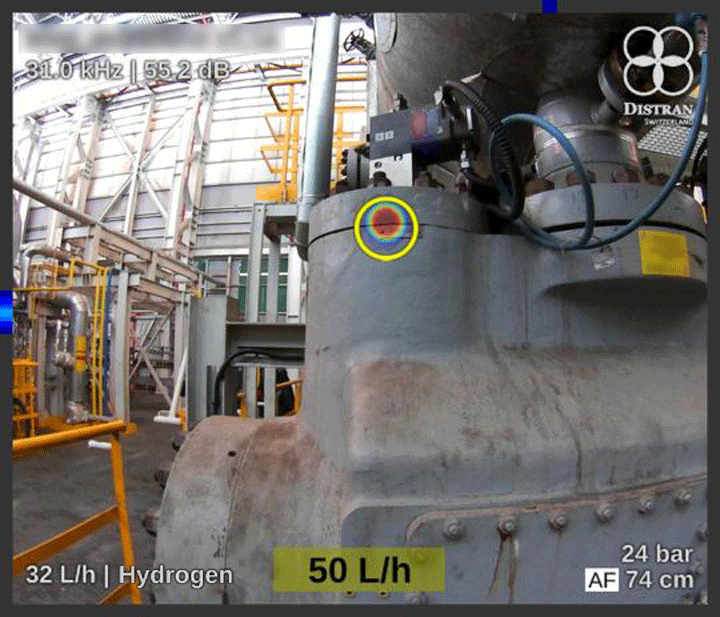

Hydrogen leaks

The Mont operations team used to spend up to five days searching a carbon nanotube reactor for hydrogen leaks. Using the Distran camera, the team spends just a few hours comprehensively covering the same area.

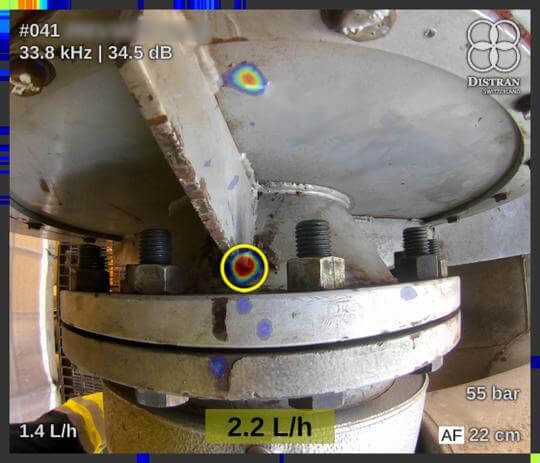

Vacuum leaks

Arkema’s vacuum installations are prone to air ingress, and detecting vacuum leaks was quite cumbersome and complex. Using the Distran acoustic camera, the operations team quickly detects vacuum leaks.

Steam leaks

Favard’s team has a preventive system to quantify steam leaks, which enables them to schedule repairs in order of importance. It’s a highly efficient and reliable process using the Distran device to check for changes in leaks each time an operator performs an inspection round.

In short, the Arkema Mont team is delighted with the Distran Ultra Pro X’s positive impact

on their site’s performance and responsiveness.

“The Ultra Pro X has become an indispensable tool.”